Product Description

Good Quality OEM Precision Injection Moulding Screw Manufacturing Injection Molded Parts

Advantages:

1. Free design and free sample.

2. CHINAMFG NDA.

3. ISO Certificated with the strict quality control system.

4. 13 Years OEM&ODM Mould-making,metal and plastic processing experience.

5. Good at spoken english and phone call communication.

6.One stop solution and drop shipment for online sellers.

Product Description

| Product Description | ODM plastic injection molding |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,…etc. |

| Standard: | ISO9001:2008 |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 15-25 Working days, Part measurement report (upon required). |

| Export Country: | All countries are reachable. |

| Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,…etc. Or as per Customer’s Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 …etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, ZheJiang made brand…etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA….etc. |

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Products show

Services

Papler Industry provides service of prototype making, mold design, mold production, mass production and assembly service in house. Our experience range from simple design to challenging technical parts.

Company Profile

Workshops and Equipments

Cooperating Customers

Packaging & Shipping

FAQ

1. Q: Where is your company or factory?

A: We are located in HangZhou, We have our own factory.

2. Q: Can you make design?

A: We’ll be glad to make mould designs for you, and for free. Complete mould 2D & 3D will supply to clients after order.

3. Q: What type of mould you can make?

A: We can make all kinds of plastic injection mould, especially rich Experience

on household moulds.

4. Q: What type of files can you accept?

A: We can accept different types of files such as DXF, DWG, IGS, IGES, STP, PRT, X_T, PDF.

5. Q: What type of steel do you use?

A: P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80,2344, S136, 4Cr13, S55C,C45#

6. Q: What kind of material you use for test mould and production?

A:PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, BMC,

We have rich experience for manufacturing product with these materials and know

how to adjust Parameter to get the perfect product.

7. Q: How to send sample?

A: The quotation we offer you including The cost of sample delivery 2 times samples by

DHL, UPS, EMS,FEDEX or TNT.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Plastic Type: | Thermosetting Plastic |

|---|---|

| Plastic Form: | Granule |

| Molding Method: | Injection Molding |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample Customized

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the key features and functions of power locks in various applications?

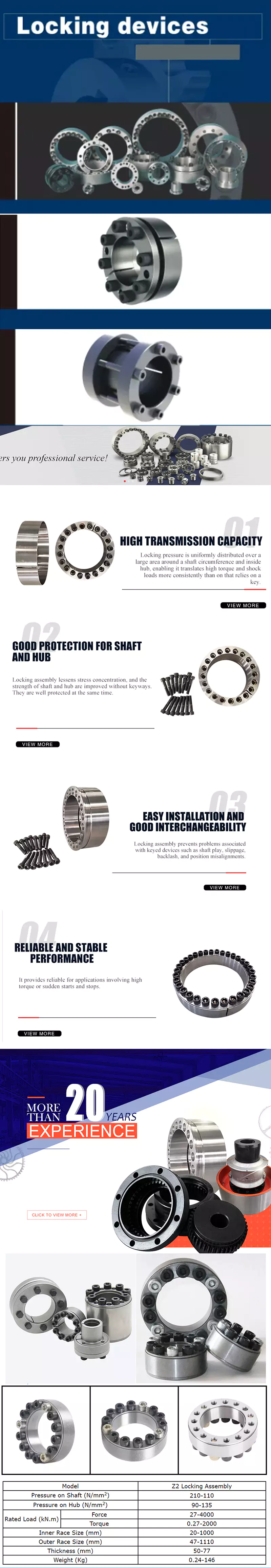

Power locks are utilized in various applications to provide secure locking and holding functions. They offer key features that ensure reliable and robust operation in diverse industries. Let’s delve into the key features and functions of power locks:

- Secure Locking: The primary function of power locks is to provide secure locking. They create a strong mechanical connection between components, preventing unintended movement, separation, or disengagement. Power locks are designed to withstand significant forces and loads, ensuring that the locked components remain securely held together even in demanding applications.

- High Strength: Power locks are constructed with materials known for their high strength and durability. They are engineered to withstand heavy loads, vibrations, impacts, and other adverse conditions. The materials used may include hardened steel, alloys, or other robust materials that can withstand the specific requirements of the application.

- Reliability: Reliability is a critical feature of power locks. They are designed to provide consistent and dependable locking performance over an extended period. Power locks undergo rigorous testing to ensure their reliability and long-term functionality, minimizing the risk of unexpected unlocking or failure during operation.

- Adjustability: Some power locks offer adjustability to accommodate different locking requirements. They may have adjustable locking positions or variable locking forces, allowing users to tailor the locking function to specific needs. This adjustability enhances the versatility and adaptability of power locks in various applications.

- Rapid Locking and Release: Power locks are designed to facilitate rapid locking and release when required. They can be actuated quickly, enabling efficient locking or unlocking of components. This feature is particularly beneficial in applications where frequent assembly, disassembly, or reconfiguration is necessary, helping to improve productivity and reduce downtime.

- Remote or Automated Control: Power locks are compatible with remote or automated control systems in many applications. They can be integrated into larger systems and controlled using electrical, hydraulic, or pneumatic actuators. This remote or automated control capability allows for centralized operation, monitoring, and synchronization with other processes or machinery.

- Safety Features: Power locks often incorporate safety features to enhance their functionality and protect personnel and equipment. These features may include locking indicators, position sensors, or fail-safe mechanisms. Locking indicators provide visual or audible feedback to confirm the successful engagement of the lock. Position sensors can detect the position or status of the power lock, enabling real-time monitoring and control. Fail-safe mechanisms ensure that the power lock defaults to a safe state in the event of power loss or system failure.

- Application-Specific Designs: Power locks are available in various designs to meet the specific needs of different applications. They can be customized in terms of size, shape, mounting options, and compatibility with existing equipment. This flexibility allows power locks to be seamlessly integrated into diverse industrial machinery, automotive systems, aerospace equipment, and other mechanical systems.

With their secure locking, high strength, reliability, adjustability, rapid locking and release, remote or automated control capabilities, safety features, and application-specific designs, power locks offer robust and versatile solutions for a wide range of applications. They play a crucial role in ensuring the stability, safety, and efficient operation of machinery and mechanical systems in various industries.

editor by CX 2024-04-17

China Good quality OEM Plastic Mould Design Threaded Screw Cover Plastic PP PC ABS Nylon Injection Molded Molding Parts

Product Description

OEM Plastic Mould Design Threaded Screw Cover Plastic PP PC ABS Nylon Injection Molded Molding Parts

| Product Material | ABS, PC, PP, PS, POM, PBT, PVC, PA6, PA66, PA66). |

| Quality Assurance | Technicians self-check in production, Engineer spot check in production, QC inspect after products finished, 100% inspection before shipment. |

| Inspection Instruments | Heigt Gauge, CMM, Universal tensile testing machine, Salt spray test box, Dynamic balance detector, Pneumatic detection, Universal hardness tester.Caliper, Electronics Scale, Micrometer/Microcaliper, Gage Blocks, Pin Gauge |

FAQ

1.How to quote?

Received the sample or drawing in CAD STP form then we will make the quotation.

2.How about the lead time?

It depends on quantity, generally 7-20 working days after order confirmation.

3.Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

4.I want to keep our design in secret, can we CHINAMFG NDA?

Sure, we will not display any customers’ design or show to other people, we can CHINAMFG NDA.

5.Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.

6. Are you trade company or manufacturer?

Senbao was founded in 2003, it owns a large factory which occupies over 10000 sq. mt in HangZhou and HangZhou. An ISO 9001:2015

& IATF 16949 & SGS &TUV Certified company, more than 140 employees.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | PP/PC/POM/ABS/PVC/PS/PE Ect |

|---|---|

| Application: | Medical, Household, Electronics, Automotive, Agricultural, Furniture |

| Certification: | TS16949, RoHS, ISO, ISO9001 |

| Samples: |

US$ 19.99/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you describe the different types of power locks, such as electromagnetic, solenoid, or motorized locks?

Power locks encompass various types that utilize different mechanisms and technologies to achieve secure locking. Here’s a description of some common types of power locks:

- Electromagnetic Locks: Electromagnetic locks, also known as maglocks, use the principle of electromagnetism to provide locking functionality. They consist of an electromagnet mounted on the door frame and a metal armature plate attached to the door. When an electric current passes through the electromagnet, it generates a magnetic field that attracts and holds the armature plate, keeping the door securely locked. Electromagnetic locks are commonly used in access control systems, such as in commercial buildings and high-security facilities.

- Solenoid Locks: Solenoid locks utilize a solenoid, which is an electromechanical device consisting of a coil of wire and a movable plunger. When an electric current is applied to the solenoid coil, it creates a magnetic field that moves the plunger. Solenoid locks typically have a bolt or latch mechanism connected to the plunger. When the solenoid is energized, the plunger extends and engages the bolt or latch, securing the lock. Solenoid locks are commonly found in applications such as cabinet locks, electronic locks, and access control systems.

- Motorized Locks: Motorized locks utilize electric motors to drive the locking mechanism. They can have various designs, including deadbolt locks, latch locks, or cam locks. Motorized locks are typically controlled electronically and can be actuated remotely or integrated into automated systems. They offer precise control over the locking and unlocking process, allowing for customization of locking positions, timing, and access control features. Motorized locks are widely used in residential and commercial applications, including smart locks and electronic door locks.

- Hydraulic and Pneumatic Locks: Hydraulic and pneumatic locks utilize fluid power to generate the force or motion needed for locking. These types of power locks often employ hydraulic or pneumatic cylinders or actuators that exert pressure to engage or disengage the locking mechanism. Hydraulic and pneumatic locks are commonly used in heavy-duty applications where high forces are required, such as in industrial machinery, construction equipment, and large-scale access control systems.

- Combination Locks: Combination locks are a type of power lock that utilizes mechanical or electronic mechanisms to secure the lock. They require a specific combination of numbers, letters, or symbols to unlock. Combination locks can be manually operated or electronically controlled, and they find application in various industries, such as safes, lockers, luggage, and security systems.

- Electronic Locks: Electronic locks encompass a wide range of power locks that utilize electronic components and technologies. They can include keypad locks, card access locks, biometric locks, or wireless locks. Electronic locks offer advanced security features, programmability, and integration with access control systems. They are commonly used in residential, commercial, and institutional settings, providing convenient, keyless entry and enhanced security measures.

These are just a few examples of the different types of power locks available. Each type offers unique features, mechanisms, and applications, allowing for versatile and secure locking solutions in various industries and equipment.

editor by CX 2024-03-24

China Js Ultra Smart Watch Ip68 Watch Ultra Reloj Intelligente Series 8 Smart Watch Sport With Compass True Screw driver side power lock not working

Non-public Mould: Yes

Model Amount: Js Extremely Wise Watch

Exhibit Sort: TFT

Monitor Resolution: 320×240

Screen: < 2

Show Shade: Shade

Function: Contact Screen, Construct in Flash, App Handle, IP67 watertight

Procedure Method: ANDROID, IOS

Digicam: No Camera

Design and style: Bar

Motion Variety: Electronic

Band Material: Silicone

Case Substance: Alloy

Purpose: Health and fitness Tracker, Contact Reminder, Answer Call, Message Reminder, Dial Call, Heart Fee Tracker, 24 hour instruction, Blood oxygen monitor

Monitor Dimension: 36-40mm

Merchandise identify: JS look at ultra sensible view

Chip: AX

Watertight Amount: IP68

Battery ability: 230mAh

Application: ZORDAI

Charging time: About 5 hrs

Guarantee: 1 Yr

BT variation: Twin BT 5.

Lifestyle time: 5-6 days for normal relationship and twenty five-35 times for standby.

Packaging Specifics: retail bundle of Js Extremely Sensible Look at Ip68 Look at Ultra Reloj Intelligente Sequence 8 Sensible Observe Sport With Compass Real Screw

Js Ultra Smart View Ip68 Observe Extremely Reloj Intelligente Sequence 8 Intelligent Look at Activity With Compass Real Screw

Our Companies

| Hardware parameters | App | FitCloudPro |

| Principal chip CPU | Realtek RTK8763EW | |

| Appropriate techniques | Android 5. and earlier mentioned iOS 10. and above | |

| Flash memory | RAM:578KB+ROM:640KB+128Mb Nor flash | |

| Screen type | IPS colour screen | |

| Monitor dimensions | 1.96 | |

| Resolution | 320*386 | |

| Touch Screen IC/Variety | Complete TP–OGS | |

| Connection parameters | BT contact | RTL8763E twin mould |

| BT | BLE5.2 | |

| WIFI | none | |

| NFC | Optional | |

| Sensor | acceleration sensor G-sensors | STK8321 |

| ECG | none | |

| Heart charge | LC09 | |

| Geomagnetism | Indeed | |

| Human body temperature | none | |

| Battery | Battery Kind | Lithium polymer battery |

| Capacity | 280mAH | |

| Charging technique | Wi-fi charging | |

| APP computer software functuion | Sports | Phase counting, energy, length, physical exercise modes |

| Health | Blood stress, heart price, blood oxygen, lengthy sitting reminder, sleep checking,automatic heart charge monitoring, and so on | |

| Smart reminder | Call, SMS, e-mail, WeChat, QQ,Facebook,Twitter,WhatsApp,LinkedIn,Instagram,Messenger,Snapchat,Line,Kakao Speak, Viber,Skype,telegram | |

| Other people | Elevate your wrist to gentle the monitor, alarm clock to remind you, get photographs by remote handle, research your mobile cellphone, etc | |

| Watch Hardware Functions | Sports knowledge | Distance, calories, steps, actual-time coronary heart price, workout length |

| Sport manner choice | Walking, operating, mountaineering, biking, basketball, swimming, china very best supplier CZPT Sq. Flanged bearing F206 pillow block bearing UCF206 badminton, soccer, elliptical device, yoga, table tennis, rope skipping, tennis, baseball, soccer, hula hoop, golf, lengthy jump, sit ups, volleyball (supporting 1 sealed deep groove ball bearing 6306 2RS 6306-2RS for Motorbike equipment Russian, Portuguese, Korean, Vietnamese, Arabic, Hebrew, Thai, Croatian, Turkish, Czech, Dutch, Indonesian, Malaysian, Finnish, Greek, Romanian, Hindi, Persian, factory default English | |

| Application language | English, Simplified Chinese, Conventional Chinese, German, French, Arabic, Czech, Greek, Spanish, Japanese, Persian, Italian, Korean, Dutch, Polish, Portuguese, Russian, Finnish, Swedish , Thai, Hungarian, Slovak, Croatian, Albanian, Turkish, Ukrainian, Hindi |

Company Data

Packaging & Delivery

FAQ

Q1. How can we know the product quality?

A1: We recommend you get samples to begin with. Or get in touch with our revenue servicer for more details .

Q2. Can it be shipped to FBA amazon warehouse ?

A2: Of course, We’ve labored with a lot of amazon stores, we have abundant encounter in labeling and can provide UPC code for you.

Q3. Can you give some photos for advertising needs ?

A3: Indeed, we can supply higher definition and stylish photographs for marketing purposes to your electronic mail .

Q4. Can you offer OEM/Customise brand on solution?

A4: Sure, You can examine information with our sales services.

Q5. What is the Warranty for your merchandise?

A5: 1 12 months guarantee for digital goods.

Q6. How to make payment ?

A6: We favor to use alibaba payment as the very first payment selection, Very hot Offering Solution CZPT 988 Agriculture Machinery Parts 5H800-11530 Tension Plate Keep Valve which can protect your business and money protected .

Symptoms of a Faulty Power Lock

Having a power lock means that you can lock your doors from the front or the driver. This is beneficial for you because you can avoid losing your keys if you forget to lock your doors. But it is also important to know that a power lock can also malfunction. Here are some of the symptoms of a faulty power lock.

Symptoms of a failed power lock

Symptoms of a failed power lock may include a blown fuse, broken wires, or an errant switch. A bad power lock actuator can result in a lockout, making the door inoperable. If you’re experiencing these symptoms, it’s time to get your hands dirty.

First, identify the components of your power lock. This includes the door lock solenoid, the wiring harness, the actuator, and the control module. If you have a faulty switch, it may be the most obvious culprit, but there are other possibilities. A fuse can also be blown, and this may be a cheaper alternative to replacing your power lock actuator.

The most important component is the actuator itself. This is an electronically controlled device that engages the lock when you press the switch. The switch sends electricity to the solenoid, which controls the locking mechanism. You’ll hear a clicking sound when you engage the lock.

Another notable feature of the power lock is the solenoid. A solenoid is a small, electromagnetic device that controls the locking mechanism. It may be damaged due to a collision or corrosion. In extreme cold, a power lock linkage may freeze, preventing it from engaging. If this occurs, the solenoid is damaged and the entire power lock system is ruined.

A power lock with a failed solenoid may operate in an inconsistent manner. It may not work as often as it should, or it may not even work at all. A failed power lock may also result in an inoperative door handle.

A failed power lock may also mean a failed power handle, which can be a frustrating situation for the driver. To remedy this problem, the handle must be firmly inserted into the door and the clip must be tightened. This should be followed by re-plugging the handle back in.

Finally, if you have a failed power lock, it’s time to visit your local dealer. A dealership will be able to provide detailed information about your vehicle’s specific components, as well as a more complete solution. Depending on the manufacturer, you may be able to have a technician replace the parts that are faulty.

Common parts that may be at fault

Having a power door lock that does not work properly can be a frustrating experience. It can prevent you from entering the vehicle or locking the doors when you get out. The good news is that it is a fairly easy fix. You may need to contact your local automotive repair shop for help.

In order to fix a power door lock, you will need to remove the door panel. Then, you will need to access the actuator. The actuator is a component that helps you lock and unlock the door. The power door lock will not work unless the actuator is working properly. You will also need to check the cables that go into the power lock and power handle. If any of them are loose, they will prevent the lock from working.

A power door lock can also be faulty due to damage or broken wires. You may also need to replace a fuse. If the fuse does not work, it will be hard to open the doors of your vehicle. If you can replace the fuse, you can restore normal functionality to your door lock.

While it may seem like a good idea to fix the power door lock yourself, it is better to take the vehicle to a mechanic. A mechanic can perform a more thorough test and diagnose the problem. If your vehicle is an older model, you may need to replace the wiring for it. You should also ask your dealership for advice.

The power door lock is one of the most commonly used features of any vehicle. If yours is malfunctioning, it is important to have it fixed as soon as possible. The problem may be as simple as a blown fuse or as complex as a broken linkage. If you cannot fix your power door lock, you may need to contact your dealer to schedule a service appointment.

In addition to a blown fuse, you can also try to fix a power door lock by replacing the door panel. This will give you a clearer view of the lock assembly.

Symptoms of a faulty actuator

Symptoms of a faulty actuator in a power lock include an erratical operation of the door locks and a random door lock that is unsettling. This issue can be caused by a power door lock actuator malfunction, or by a switch problem. The best way to troubleshoot the issue is to take it to a mechanic.

Faulty actuators can make strange noises when the doors are locked or unlocked. If the noises become louder, you may have worn out gears or a motor. This can lead to random door locking, which is a serious safety issue for any car owner.

The first step in diagnosing a power door lock actuator failure is to locate the actuator. The actuator can be located inside the door panel or near the door latch. It is usually connected to the door latch assembly by plastic clips or screws.

If the actuator is not visible, then you can try to access it by removing the door cover. Then, you can probe the electrical connector of the actuator with an automotive meter. If the meter registers 12 volts in both directions, then it is likely that the actuator is working properly. However, if the meter shows negative in one direction, then the actuator is not working properly. Then, it may be a problem with the solenoid, the door lock switch, or the electrical wiring.

Symptoms of a faulty actuator are similar to those of a broken door switch. They may be intermittent, and you may hear a clicking sound. However, it is possible for the actuator to work sometimes, and not work at all. If the actuator is faulty, you may need to replace it.

If the actuator is not working, you may also need to replace the switch or the wiring harness. This can be complicated. It is important to ensure that all the cables in the lock assembly are accounted for. This includes cables from the power handle. If the cables are broken or frayed, they will not work properly.

If your vehicle is under warranty, it may be a good idea to take it to your local mechanic for assistance. They will be able to provide you with detailed information about your power door lock actuator issue.

Changing the lock switch

Changing the power lock switch in your vehicle can be a simple process that helps your car run efficiently and safely. However, if you are not careful, it can also lead to a dangerous situation.

The power door lock switch is a central locking feature located on every door in your vehicle. It is also found on the central console of some vehicles. This is the part that allows you to lock and unlock your doors using a button. In addition, it is used to secure the internal valuables of your vehicle.

It is important to be aware of the signs that may indicate that your power door lock switch needs to be replaced. If you are experiencing a problem with the power door lock, you may have a faulty switch that is causing your door to lock and unlock randomly. This is a problem that can happen at any time. A faulty switch may be caused by electrical issues, wear and tear, or other problems.

The power door lock switch may also be exposed to harsh elements that may cause it to wear out. This can include exposure to rain, snow, and other outside elements. These elements can also affect the electrical contacts inside the switch. When these contacts become worn out, the switch will lock and unlock too quickly. This can cause a driver to get distracted and cause unsafe driving conditions.

Another common problem with door-mounted electronics is moisture in the switch. This is usually caused by corrosion or wear and tear. It is best to have the switch checked by a mechanic so they can determine whether the switch is faulty. If moisture is present, it is a good idea to replace the switch as soon as possible.

Once you have identified that your power door lock switch needs to be changed, you will want to get a quote for the cost of replacing the switch. A mechanic can provide you with a price estimate based on the condition of your switch. Most mechanics charge between $80 and $120 an hour. However, if there is further damage to the door mechanism, this may increase the labor cost.

editor by czh 2023-03-22