Product Description

| Item | Content | Unit | Model | ||

| 3WPZ-700A | 3WPZ-700L | 3WPZ-700K | |||

| Overall Size | Dimensions | mm | 5950×2571×2980 | 4850×2450×3070 | 4700×2050×2900 |

| Boom Length | mm | 14350 | 17350 | 11200 | |

| Boom Lifting Height | mm | 500-1800 | 500-1800 | 500-1800 | |

| Ground Clearance | m | 1.1 | 1.05 | 1.02 | |

| Wheel Base | mm | 2050 | 2050 | 2050 | |

| Wheel Track | mm | 1520 | 1800 | 1500 | |

| Cab type | / | canopy | canopy | canopy | |

| Spraying System | Working Pressure | Mpa | 0.2-0.5 | 0.2-0.5 | 0.2-0.5 |

| Tank Capacity | L | 700 (LLDPE) | 700 (LLDPE) | 700 (LLDPE) | |

| Mixing Mode of Pesticide | / | Jet Flow+Back Flow | Jet Flow+Back Flow | Jet Flow+Back Flow | |

| Spraying Width | m | 15 | 18 | 12 | |

| Working efficiency | m2/h | 45000-56000 | 50000-60000 | 40000-50000 | |

| Fuel consumption | liter/h | 6 | 6 | 6 | |

| Nozzle Type | / | Cone Spray/32 pcs | Cone Spray/38 pcs | Cone Spray/24 pcs | |

| Material of Boom | / | Aluminium Alloy | Aluminium Alloy | Aluminium Alloy | |

| Position of Boom | / | Front | Front | Front | |

| Structure Type of Liquid Pump | / | Three Cylinder Plunger Pump | Three Cylinder Plunger Pump | Three Cylinder Plunger Pump | |

| Driving Mode of Liquid Pump | / | Hydraulic | Hydraulic | Hydraulic | |

| Engine System | Rated Power | kw/rpm | 36.8/2400 | 36.8/2400 | 36.8/2400 |

| Battery Capacity | / | 24V 60AH | 24V 60AH | 24V 60AH | |

| Driving System (3+2)x2 | Driving Type | / | 4WD | 4WD | 4WD |

| Steering Type | / | 4WS | 4WS | 4WS | |

| Tire Type | / | Pneumatic | Pneumatic | Pneumatic | |

| Tire Outer Diameter | mm | 1200 | 1400 | 940 | |

| Tire Width | mm | 130 | 130 | 120 | |

| Drive Axle Style | / | Front and Rear Differential Lock | Front and Rear Differential Lock | Front and Rear Differential Lock | |

| Turning radius | mm | 3000 | 3500 | 2900 | |

| Driving speed | km/h | 0-24 | 0-24 | 0-24 | |

| Fertilizer spreader | Spreading width | m | 15 | 18 | 15 |

| Fertilizer tank | liter | 350 | 350 | 350 | |

| Optional | Double disc type fertilizer spreader | no | |||

Product Description

1. New self-designed sixth-generation high-end drive axle, can adapt to various harsh environments;

2. The four-wheel steering, less pressure seedlings,flexible control;

3.The machine design is ergonomically verified, with small turning radius;

4. convenient maintenance, spacious and comfortable driving space;

5. Spraying and spreading fertilizer can be carried out at the same time to meet the needs of high-end users.

Company Profile

Xiangrui is a professional company manufacturing self-propelled boom sprayer of 700 liters,1000 liters,1300 liters,2000 liters and 4000 liters, which are widely used for spraying rice, wheat, corn, soybean,vegetables and other crops, greatly improving labor efficiency and pesticide utilization.

There are 11 professional technicians, who have many years of experience in plant protection machines, Our company has passed the ISO9001 quality management system certification, CE, national compulsory product 3C certification.

Certifications

Packaging & Shipping

FAQ

Q1: Manufacturer or Trading Company?

We are a manufacturer since 2014.

Q2: How about the quality?

Our self-propelled boom sprayer sales is no. 1 in China, the quality is very good.

Q3: What’s the delivery time?

Normally 15 days after receiving deposit.

Q4: How about the gurantee?

Our axle guarantee is 2 years!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Engine Power: | 36.8/2400 Kw/R/Min |

|---|---|

| Spray Range: | 15 M |

| After-sales Service: | 1 Year |

| Warranty: | 1 Year |

| Installation: | Self-Propelled |

| Liquid Contained: | Disinfector, Pesticide |

| Customization: |

Available

| Customized Request |

|---|

The Benefits of a Power Lock

Regardless of whether you are the owner of a classic car or a new model, a power lock is a must. It allows you to lock and unlock your car from the front passenger seat without having to rely on the keys.

Traditional power door lock

Using a traditional power door lock is one of those things that you may not have thought of. This is largely due to the fact that there are a wide variety of modern vehicles that include such features in their stead. They are usually fitted to four-door cars in particular, but some models can even lock and unlock the trunk! Aside from being convenient, a power door lock is also a safety feature, as it is designed to keep children from exiting a vehicle with the door open.

Aside from a power door lock, there are a variety of other ways to improve the safety of your family and cargo. You can also have your fuel cap covered with a button or switch! In addition, there are many options that make it easier for you to monitor your vehicle from afar. This is particularly useful if you’re traveling alone. The best way to go about this is to use a mobile app. The best ones are free and are compatible with all makes and models of automobiles.

You may also want to look into getting a keyless locking system for your home or office. These are available in all shapes and sizes, from the cheap and cheerful to the posh. Some are hardwired for electricity, while others use backup batteries. You can also choose between two and four door models.

Keypad door lock

Whether you need a keypad door lock for your business or residential application, there are several options available. You will need to determine what features are important to you and then choose a lock that provides those features.

A keypad door lock is an electronic or mechanical lock that requires the user to enter a code to unlock the door. This type of lock is used most often in the workplace or on external doors. It helps reduce the risk of unauthorized user error by eliminating the need for a separate key.

Keypads are easy to set up and use, and provide a high level of security. Many keypads have a touchscreen and allow for multiple users. Keypads can also be connected to a home network so that you can lock and unlock your door remotely. Some keypads also have a security feature that prevents opening after several failed attempts.

Keypads are also easier to program than standard locks. You can set the locks to give you temporary codes or to require you to change codes on a regular basis. In addition, some keypad locks allow you to share your code with other people. Some locks even provide audio tones to help verify that you have entered the correct code.

You can also choose a lock that allows you to use a mobile application to control the lock. This allows you to lock and unlock your door remotely, or to allow other people to open your door.

CZPT cylinders

CZPT cylinders aren’t exactly hard to find, but they aren’t always easy to install. The best way to go about it is to hire a certified professional and take a little time to learn the ins and outs of the cylinder and the lockset you are installing. This will help ensure the best possible outcome. Moreover, a professional will be able to help you determine which power lock is right for your situation. CZPT cylinders are made of metal, so you’ll have to get used to a little bit of metal on metal. You’ll also want to be prepared for a few rough patches. Luckily, there are some cylinders that come with a warranty, so you can rest assured that you’ll have the best possible lock for a price that’s both affordable and reasonable. Choosing the wrong power lock could lead to major headaches down the road.

The best cylinders come from a company known for its quality products and customer service. For the discerning consumer, you can find a full line of cylinders in a variety of styles and finishes. If you have a cylinder in your household, chances are good that you’ll have to have your cylinders replaced at some point. Luckily, Luter has got you covered. The company carries a full line of cylinders, including the aforementioned CZPT cylinder, in addition to other styles of locks like the rim, rim cylinder, and Euro profile cylinders.

Symptoms of a faulty lock switch or blown fuse

Symptoms of a faulty lock switch or blown fuse in a power lock are often simple to identify. You should start by checking the wiring harness running from the door frame to the door. If you notice a frayed wire insulation, this could be the culprit.

You should also check the voltage at the door lock switch to determine if it is functioning properly. If it isn’t, you may need to replace the switch or actuator. You can find these parts at any auto parts store.

You may also need to replace the fuse that powers the door lock actuator. This fuse is responsible for converting rotational motions into linear motions. If the actuator fails, you will hear weird noises when you press the lock button or try to open the door.

The key to a successful power lock repair is to ensure you get the right fuse for your vehicle. This is because automotive fuses are made with different materials and amperage ratings. The best way to find the right fuse is to read your owner’s manual. It should list the amperage ratings for each fuse in your vehicle.

It is also important to note that a blown fuse will typically deactivate the circuit it is responsible for powering. If you are experiencing intermittent shorts in the wiring, this can also cause a fuse to blow.

The volt meter can also be used to determine if you have the correct voltage to the lock switches. You should follow the instruction on the volt meter to get the best results.

In addition to checking the voltage at the lock switch, you should also check the voltage at the door lock actuator. If the voltage is not present at the door lock actuator, you may need to replace the switch or the actuator.

Common uses for power locks

Almost every modern vehicle features power locks. They add automation to locking doors and are easy to use. Some vehicles even allow the driver to lock all doors at once.

These locks are available in many different forms. Some are mechanical and others are electronic. They can also be used with access control systems.

Mechanical locks have a cylinder that is held in place by a series of small metal pins. They are often made of corrosion-resistant materials. They are difficult to break with a bolt cutter.

Electronic locks are triggered by a numerical keypad mounted on the door. They operate on the same principle as solenoid locks. An electrical impulse may be triggered by a wireless remote control sensor or a keypad. These locks allow users to set multiple combinations.

Some electronic locks have a replaceable battery. This may be required if the power fails. A back-up power source is important in secure areas.

Magnetic strikes are another type of power lock. These are used in doors that protect secure areas. They are inexpensive and provide single-sided security. They are ideal for doors that will be locked in an emergency. They are also easy to install. They have less wear than electric strikes and are easier to maintain.

A magnetic strike will also require a back-up power source. They may also need to be replaced if they lose power.

Electronic locks are also used in business settings. They allow businesses to secure their location and offer a convenient way to access doors after business hours. They can also be set to automatically lock or unlock during certain times. They can also send digital access codes to visitors.

editor by CX 2024-03-26

China OEM China Water Cooled CZPT 27.5kv/27.5kVA/22kw 60Hz Three Phasece Diesel Mechinical Power Ultrasonic for Philippine in The Logistics Genset Price with ATS power bi lock filter

Product Description

China Water Cooled CZPT 27.5kv/27.5kva/22kw 60hz Three Phasece Diesel Mechinical Power Ultrasonic for Philippine in The Logistics Genset Price with ATS

ONEW diesel generators are strong-built, ideal for emergency back-up,job sites and industrial appplications.

Powered by reliable air/water cooled diesel generators sets, industrial grade, great fuel efficiency, less maintenance, long operating life.

Low oil shut-down provides added safety against engine damage.

8-10hours long run fuel tanktank with fuel gauge.

stainless steel parts with door lock and hinge fuel tank lock.

Strong frame/capony, durable and strong protection and security on the job.

Hour meter / maintenance resets – easily monitor run time and track maintenance intervals.

Optional ATS sockets for connecting with an external automatic transfer switch.

|

genset type |

rated output |

Engine |

Alternator |

control |

|

KW/KVA |

model |

model |

Comap |

|

|

GF2-111 |

24/30 |

R6105ZLDS |

ON-30 |

Comap |

|

Genset SIZE |

2700x1050x1470mm(4.42cbm) |

|||

|

Weight |

1295kgs |

|||

|

Fuel comsuptions 100%Loading |

24L/H |

|||

|

Base Fuel tank |

8-10hours fuel tank |

|||

|

Engine Data sheet |

||||

|

Engine model |

R6105ZLDS |

% |

≤5 |

|

|

Type |

Water cooling,in line,four-stroke,wet liner and direct injection |

Mpa |

0.3-0.5 |

|

|

Number of cylinders |

6 |

r/min |

≤650 |

|

|

Bore/Stroke mm |

105-125 |

Mpa |

≥0.10 |

|

|

Displancement L |

6.49 |

g/kW.h |

1.63 |

|

|

Compression ratio |

16:1 |

L |

18 |

|

|

Aspiration |

turbo & inter cooler |

Starting method |

Electric motor start |

|

|

Rated output kW |

20 |

Lubricating method |

Pressure lubrication |

|

|

Rated speed r/min |

1500 |

Crankshaft rotating direction |

Counter clockwise(face to output end) |

|

|

g/kW.h |

≤231 |

Fring order |

1-5-3-6-2-4 |

|

|

r/min |

≤1575 |

Net mass kg |

620 |

|

|

Alternator data sheet |

||||

|

Brnad |

Copy stamford |

Pressure regulating mode |

AVR automatic pressure regulation |

|

|

model |

ON-30 |

bearing |

Long life and no need maintencances |

|

|

Prime power |

24kw |

Class of insulation |

H grade |

|

|

Exciation mode |

Brushless self-excitation |

protection |

IP23 |

|

|

Power factor |

0.8 |

|

||

ONEW has been focusing solely on diesel products since day one.Products includes AIR/WATER COOLED DIESEL ENGINES, GENERATORS sets and Spare Parts. ONEW Generators to power their homes, factory, contructions,resell, etc.

Warranty

The products will be tested stricly 1 by 1 before delivery with testing video to customer.

Germany production processes and quality standards to guarantee the good quality.

Our warranty is 1 year or 1000 running hours whichever comes first.

But based on some special project,we can extended our warranty period.

Please help us to find out the problem, and we will offer free components for service.

All products will be well packaged and will not be damaged in transit.

FAQ

1.How to buy your product?

You can place an order directly through the start order of Made in china

or send email ,add to talk

2.Do buyers need to contact the seller after placing an order?

No, we will contact you as soon as possible by made in china and prepare to ship.

3.How long does it take to receive the product after placing an order?

3-15 days from deposit, after your order, we will contact you and tell you the specific time.

4.how many MOQ?

MOQ is 1

5. Are you a manufacturer or trading company?

We have large factorys, R&D teams and foreign trade teams.

6.How spare parts supply of generator?

We can send u free spare parts during warranty by DHL

7.What kind of diesel use?

#0 diesel

8.How could I trust you?

Diesel Service & Supply stands behind the quality of all the used generators and industrial power equipment we sell. If you are not convinced by the pictures, videos, check-in reports, load tests, customer experiences and sales associates’ knowledge about the generator you are interested in, then we invite you to come visit our expansive yard and shop facility to witness a load test and see the professional operation we have going on here.

ONLINE PAYMENT TRADE ASSURANCE AVAILABLE

If You Are Interesting In ONEW, Pls Contace Us Freely ,Welcome To Visit ONEW!!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Self-Starting Diesel Generator |

|---|---|

| Installation Method: | Fixed |

| Stroke: | Four Stroke |

| Cooling Method: | Water Cooling |

| Output Type: | AC Three Phase |

| Speed: | Speed |

| Samples: |

US$ 2799/SET

1 SET(Min.Order) | |

|---|

How to Install a Power Lock for CZPT Cylinders

Having a power lock on your car will let you have control over the door locks on your car, allowing you to lock them or unlock them. In addition, you will have the option of using your front passenger’s power lock.

Traditional power door lock

Probably the most common car door lock is the traditional power door lock. These doors are often a nice perk for those who travel alone or have young children in tow. These devices can be found in nearly all of today’s top-line vehicles. They can be unlocked using a button on the inside of the car, or with a combination lock placed outside the door. They are also accompanied by a power door lock control panel on the driver’s side. Most also have backup batteries. They also come in two-door and four-door models.

They can be found on virtually every new car on the road. This technology is most commonly found in modern family cars. The most recent models also include an automatic fuel cap release function. These devices are best described as the modern day equivalents of a key pad. The keyless systems are more streamlined, but they also lack some of the charm of the classic locks. Those who can’t get their hands on a keypad can usually unlock the door with a push of a button or a swipe of a key fob.

Unlike the old-fashioned keypad, these are mechanically operated, and can be hard-wired to electricity. They can be found in a wide range of finishes. The most prestigious vehicles are likely to come with a power door lock, but it’s also quite common to find them as an option on less expensive vehicles. They are also a good choice for families with young children. Some keyless models even come with backup batteries. The traditional power door lock can be a bit pricey, but the latest models come with a standard warranty and are often available at bargain prices.

CZPT cylinders

Getting a power lock for CZPT cylinders installed is not as simple as it sounds. The best way to go about it is to get a professional to do it for you. You’ll be rewarded with an added layer of security and peace of mind. If you choose to go the DIY route, be sure to take into consideration the following tips and tricks.

First, the cylinder is located at the bottom of the door, as opposed to the top. Second, be sure to take into account the type of door you have. This will help you decide whether a power lock for CZPT cylinders is best suited for your entryway. Finally, make sure to get the cylinder from a reputable source. This will help ensure you get a quality lock that will last. A power lock for CZPT cylinders is a great way to add an extra layer of security to your home. Getting one installed correctly is the best way to go about it. This is the only way to guarantee you’ll get a quality lock that will last.

The power lock for CZPT cylinders is a small price to pay for the increased security and peace of mind. When you’re ready to replace your old locks, check out CZPT Lock’s line of products for a complete range of high security locks and accessories. Whether you’re looking for a security upgrade, new locks for your home or office, or need a new lock for your car, CZPT has a lock for you. With their high quality products, you can be sure you’ll find a lock that will meet your security needs. Get started today!

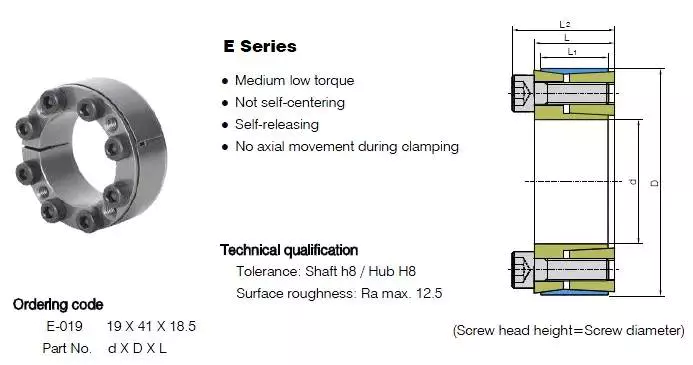

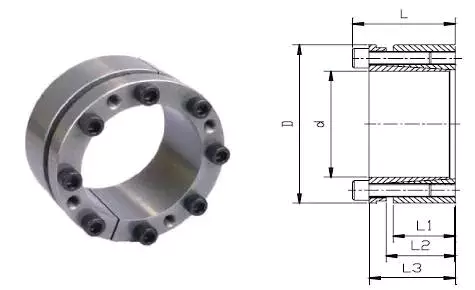

CZPT Power-Locks

Using CZPT Power-Locks is an effective way to improve the connection of drive components to a shaft. These devices are designed to lock onto a shaft and prevent backlash from occurring. They also offer extreme clamping strength for rotational components. In addition, they have a number of features that make them ideal for use in industrial applications.

CZPT Power-Locks have many benefits, including the ability to handle high torque, high thrust, and dynamic loads. They can also be used to connect small and large sprockets, timing pulleys, gears, conveyor pulleys, and more. They also feature a precision made double taper design.

Power-Locks are made from high grade materials and are available in stainless steel, electroless nickel plated steel, and aluminum. They are available in metric shaft sizes up to 11 11/16″, and inch shaft sizes up to 4.5″. They are also available in a variety of bore sizes, from 19 to 500mm. They are adjustable and have no assembly required, making them a convenient and cost-effective way to attach shafts to hubs. They also allow for transmission of high torque and axial loads, reversing, and dynamic or shock loads. They also reduce machining costs and are easy to assemble.

CZPT Power-Locks are available from CZPT of Canada, Ltd. and can be ordered online. They are available in a variety of sizes and models, making them suitable for both common and industrial applications. They can also be ordered in the form of ball and cage assemblies, which are ideal for securing small gears or other rotational components. They are also available at leading prices. They are available in several materials, including poly amide cages, and ball and cage assemblies.

Faulty actuators

Whether you have a newer or older vehicle, chances are you’ve heard the term “faulty actuators in power lock.” While these actuators are a relatively simple component of a power door lock, they can malfunction, leading to a variety of problems.

The actuators used in most power door locks are motors and gears that work together to convert the motion of the motor to lock or unlock the door. When a door is locked, the actuator is activated by a key inside the door.

If you’ve experienced a faulty door lock actuator, there are a number of things you can do to fix it. In some cases, you can try to replace the fuse or switch. But, in most cases, you’ll need to replace the entire latch assembly. This can cost anywhere from $150 to $300 depending on the type of car.

Test all of your vehicle’s doors

Luckily, most manufacturers offer a power lock bundled with the base model. Besides, if your car is on the road less than three hours a day, you are likely to be in the vicinity of your local dealer anyway. If you haven’t had your doors rekeyed in the last few years, you’ll probably be getting the runaround from your dealer’s door department. Fortunately, most dealers are happy to test and rekey your car for you for a small fee. To make the process go as smoothly as possible, use a quality automotive locksmith. In my experience, a competent mechanic can have a door open in less than an hour. The cost of the power lock bundled with the base model will not break the bank.

editor by CX 2024-03-26

China factory Faith 50/100W Mini Low Power Backpack Fiber Laser Cleaning Machine power lock dead space

Product Description

Faith 50W/100W Portable Laser Cleaning Machine

Product features

1 . Non-contact cleaning , does not damage the parts substrate

2 . Precise cleaning , which can achieve selective cleaning of precise location and precise size

3 . No chemical cleaning solution , no consumables , safe and environmentally friendly

4 . The operation is simple , just power on , and it can be hand-held or cooperated with the manipulator to realize automatic cleaning.

5 .The cleaning efficiency is very high , saving time

6 .The laser cleaning system is stable and requires almost no maintenance.

7. One-time investment , cost-effective

01 Handle button Unique design one-button openingand closing is easy to operate

02 Warning light handle Unique design with built-in safety lock

Strong and durable , beautiful and eye-catching

Green is normal . red is in working state

03 Safety switch

04 Display Small and smart

Easy to operate and more humanized

05 Air outlet Large displacement , strong heat

Dissipation , novel appearance

06 Fiber exit Compact and beautiful

07 Power interface Easy to push and pull,durable

08 Strap buckle Hang the straps to free your handseasy to carry

09 Rubber feet Small and beautiful , more non-slip

FEATURES AT A GLANCE

Mini laser cleaning machine

Product Parameters

Laser cleaning machine size

|

Laser source |

fiber laser |

|

Laser Power |

50W,100W |

|

Laser Wavelength |

1064nm |

|

Laser power adjustment |

10%-100% continuous gradient adjustable |

|

Scan Width |

0mm-100mm available |

|

Pulse Energy |

1 mJ |

|

Cooling |

Air cooling |

|

Light Pass Rate |

≥98% |

|

Laser pulse frequency adjustment |

1kHz-4000kHz continuous fade adjustable (support customization) |

|

Focal length |

Standard 160mm (210mm/254mm/330mm/420mm optional) |

Laser Head Size

50W Product Size

100W Product Size

Appliaction

Application Cleaning Samples

Favored by fabricators of auto parts , rubber molds , high-end machine tools , tire molds ,

rails and more , this pulsed laser cleaning machine handles rusts , oil , paints , coating ,

oxide layer , resin and other contamination in a more controllable and precise way while

making processes more reliable and energy-efficient

Please contact me if you are interested!

FAQ

1.What are the primary products of your company?

Our primary products include laser marking machine, inkjet printer machine,paging machine.

2.Where is your laser marking machine applied to?

Our laser equipment is applied to metal, non-metal, textiles, leather, shoes, advertisement, gifts, electronic components, stamp,etc

3.Which countries are your laser machinery sold to?

Our products are widely exported to Poland, Russia, Ukraine, Korea, Thailand, Egypt, Brazil, Australia, Singapore, Saudi Arabia,

Turkey, India, Italy, and other countries.

4.How long is the delivery time?

The products will be delivered to you within 1 week after the order is confirmed.

5.What certificate has your company got?

All of our product with CE, ISO

Certificate

About company

HangZhou Faith Technology Co., Ltd. is a high-tech enterprise, which integrates independent research and development, production, sales and service. It specializes in providing industrial coding technology and traceable system solutions. The company was founded in 2571 with a 30-person team and a 500m² production workshop. After more than 10 years of unremitting efforts, by early 2571, it has developed into an excellent team of 300 people and a 2500m² production workshop. The company’s products mainly include laser marking machines, CIJ printers, TIJ printers, and conveyor belts. The products are exported to Spain, the United States, Brazil, Argentina, Chile, Saudi Arabia, the UAE, Egypt, Ecuador and other 126 countries, serving more than 200,000 customers. The company’s philosophy is focus on coding, treats quality as the base and service-oriented principles. HangZhou Faith Technology’s vision is to become the most professional, caring and trustworthy enterprise in the printing industry.

For more than 11 years, Faith products have been exported to 126 countries, occupying 7% of the industry’s market share, and customers all over the world

If you have any questions, please feel free to contact me, I will do my best to give you a satisfactory answer.

what service can we provide for you?

24 hours after sales online, / no matter you are looking for help anywhere, anytime, we can respond quickly

Excellent technical consultant, provide the best online solution.

Three-year warranty, during the warranty period we provide professional, considerate and timely after-sales service.

Give back

For more than 10 years, Faith products have been exported to 126 countries, accounting for 7% of the industry’s market share, and customers all over the world have won unanimous praise from everyone.

After payment is completed, your order will be shipped within 3 days

We use express ups, dhl, ems, fedex, and the package will Feed Backreach your hand in 3-12 business days.

Please contact me if you are interested!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Video Support and Free Spare Parts |

|---|---|

| Power: | 50w |

| Control Type: | Automatic |

| Samples: |

US$ 4411/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Using a Power Lock

Using a power lock in your vehicle allows you to lock the doors without having to take your hands off the wheel. It is also great for front passengers to use.

Actuator

Among the most common features on any vehicle are power door locks. These locks work by turning a gear mechanism and lock or unlock the door. The gear mechanism is made of an electric motor and spur gears.

Power door lock actuators are critical to the operation of a power door lock feature. When a power door lock actuator fails, it disables the power door lock feature.

The most common complaint about a power door lock actuator is that it locks and unlocks intermittently. This may be due to a problem with the wiring or circuits.

Some symptoms of a faulty power door lock actuator are noises coming from inside the door. For example, when a motor is not turning, it will make a loud “clunk” sound. When a motor is working properly, there will be little or no noise.

A faulty power door lock actuator may also cause a car to lock and unlock randomly. This can happen due to a faulty circuit or circuits wearing out.

Alternatively, a faulty actuator may be the result of a water leak in the door. If this is the case, the water may enter the door lock actuator and cause it to malfunction. Fortunately, there are a number of ways to check the condition of your actuator and fix any problems.

Body controller

Almost all modern day cars have some form of power lock, but only a select few have a body controller to boot. The fancy name is the electronic control unit, but the acronym ECU stands for Electronic Control Unit, or ECU for short. The ECU is responsible for coordinating the myriad electronic components that are dotted throughout your vehicle’s occupant compartment. It also controls things like power windows and the air conditioning. You can see the ECU in action by glancing at your dashboard. It’s a small and power-packed box, but a discerning eye will spot a few stragglers amongst the more mundane tasks. The ECU is also responsible for ensuring the safety of passengers by ensuring that the doors remain unlocked until a specified interval.

The ECU’s lesser known cousins, like the power door lock, are only responsible for a few of the more mundane tasks. Aside from the usual suspects, the ECU also manages the power mirrors and the power windows, albeit on a less than optimal schedule. A faulty ECU isn’t quite as funky as it sounds, and can be rectified by a trip to the local mechanic. If you’re not a mechanic, you’ll likely be able to remedy the situation with a simple door lock replacement.

Check for broken wires

Occasionally, you will need to check for broken wires when using a power lock. Having a broken wire will require you to repair it, or replace it with a new one. However, this process can be quite difficult, as it is hard to reach the motor. If you are unsure what wires are connected to your vehicle, you should consult a wiring diagram. If you do not have a diagram, you can also use a multimeter to check for continuity across all wires. However, a multimeter is not enough to check for broken wires. You will also need rubber gloves to do this safely.

To check for broken wires, first make sure you have access to the wires that are in the lock motor. These are usually located near the plug on the door frame. If you can’t reach them, you can use jumper wires to connect the actuator to the 12 volt power supply and test it for power. If this does not work, you will need to remove the lock motor from its electronic control board and check for a broken wire harness. However, if this is not possible, you can use a Power Probe to apply 12 volts to the actuator.

editor by CX 2024-03-25

China wholesaler 8 Inch Bore Pneumatic Chuck Kl08q-3 Power Chuck for Milling Machine power lock app

Product Description

CNC lathe vertical 3 jaw pneumatic chuck

Pneumatic power chuck

Working principle: the clamping power source of the chuck is compressed air; when compressed air flows into the one-way valve through a distributing ring and then into the chuck cylinder, thus to drive the piston, so that the jaw clips a workpiece tightly; then, the reversing valve is powered off, and the air pressure within the cylinder is sealed by the one-way valve. The sealing device of the distributing ring is released, not to contact the chuck body, and the equipment can be started for normal work at this time. Note: because the chuck is ventilated in the clamping and released state, and the special sealing element on the distributing ring clamps the excircle of the chuck body tightly, so the machine tool spindle should stop rotating while the chuck is clamping and releasing the workpiece. Parameters

|

Spec |

A |

B |

C |

D |

|

KL04Q-3 |

115 |

72 |

140 |

158 |

|

KL05Q-3 |

138 |

95 |

150 |

175 |

|

KL06Q-3 |

165 |

130 |

190 |

218 |

|

KL08Q-3 |

215 |

165 |

222 |

265 |

|

KL10Q-3 |

256 |

206 |

270 |

310 |

Company profile:

Xihu (West Lake) Dis.uan Thor Machinery Co., Ltd is specialized in producing various sorts and specifications of machine tool accessories and Universal cutter and tool grinder. Our main product are: Drill grinder, end mill grinder, screw tap grinder, chamfering machine, cutter grinder, Tool grinder, saw blade sharpener, lathe tool grinder, ejector pin cutting off machine, dividing head, rotary table etc. Product have reliable quality and long term export to USA, Europe, Asia, South America etc.

With high precision and full varieties are deeply trusted and appreciated by customers both at home and abroad. Products are widely used in machinery manufacturing, CZPT making, printing, advertisement sculpture, paper making, Bridges, mechanical lock, woodworking machinery and other industries. Our company has a group of professional technician and after-sales service people, it have a comprehensive quality control and management in the production or sale, welcome to inquire and visit.The comments and feedback of enduser and dealers is important informatiois to improve the quality of our products , and also good chance to improving the development and production of the product and service way.Thor Team in line with “quality, honesty, innovation, service” purposes, adhere to the concept of excellence. With reliable quality and advanced technology, we can lead in the forefront of the Times.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What’s your main products of your company?

A: We specialized in all kinds of machines ,such as Tapping machine, end mill grinder, drill grinder, cutter grinder, chamfering machine ,dividing head, rotary table and so on .

3. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

4: What’s the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

5: What’s the MOQ?

A: 1 set . We want to know: a.What’s your Industrial Voltage? b.We strongly suggest you to tell us size, material of your workpiece for our evaluation, if possible, better to send us workpiece drawing, so that we can recommend you most suitable model! c.If need CIF Price, please kindly tell us the port of destination.

6:What is your sea port?

A: HangZhou/ZheJiang /HangZhou Can we use our own LOGO or design for sticker? A: Yes,you can contact with the salesman. And sent us more details about the LOGO or sticker.

7. How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

| Certification: | CE |

|---|---|

| Application: | Grinding Machine, Milling Machine, Drilling Machine, CNC Lathe Machine |

| Jaw Type: | Soft Jaw |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Power Lock Actuator Problems

Having a power lock installed in your vehicle is an extremely usef”ul tool, allowing you to lock the doors while parked. Having a power lock in your car also allows you to unlock the doors when you want to leave, which is extremely useful when you have small children or pets in the vehicle.

Body controllers dictate the locking and unlocking of power door locks

Using the power door locks of your choice, it is possible to lock or unlock your vehicle without ever having to touch your keys. However, that isn’t the case for every driver. In fact, some motorists are so enthralled by their power door locks that they are oblivious to the fact that the doors are locked until they slam their brake pedal. The body controllers on the other hand take care of that problem – and many more – for you. It even manages to keep your interior lights on while you’re cruising down the highway. In short, the body controller is the best thing to have in your car. Moreover, it can be reprogrammed to do all of your power door locks in one fell swoop. A few years back, this was a feat in and of itself, but in this day and age of driverless cars, it has become a necessity.

The body controller is the brains behind the power door locks of your choice, as well as the vehicle security systems. It even manages to keep your interior illuminated even as you make a beeline for the nearest gas station. The body controller even keeps track of which doors are open and which are locked. It can also be used to remotely control other door locks via the same key fob or via a wireless remote, in the event you need to unlock a specific door. It even manages to do all this with the minimal intrusion to your wallet. And if you’re one of the lucky few, it even offers an onboard diagnostics center, a feature that many competing brands aren’t so keen on.

Actuator motors

Using the right parts from the right suppliers can ensure that your power lock actuator will last you a lifetime. The cost of replacement parts is a fraction of the cost of a new car. A new power lock actuator will give you the confidence that your family and your valuable possessions will be safe from the vagaries of life. The best part is that your car will be the envy of the neighborhood. After you’ve made the purchase, a few minutes of the requisite chitchat is all it will take to get the job done.

You’ll be well on your way to the happy ever after in no time. Taking the time to test the power door actuator may be well worth the time and the effort. After all, a new vehicle is an investment in your life, not to mention the resale value of your possessions. Unlike the old school, the power door actuator is located in the driver’s side of your vehicle and the power door is inaccessible from the front passenger door. You can even opt to have it mounted in the trunk for easy access during those emergency road trips. The power door actuator is a small but mighty machine. Besides, your family and your belongings are safe from the scoundrels in the back seat. Keeping your family safe and secure is important whether it’s a quick stop at the coffee shop or a day out at the beach. Getting the best power door actuator is the best way to keep your loved ones safe from the scoundrels in your vehicle. Having your car in the best condition possible can be the difference between getting a call or having a full night’s sleep.

Faulty switches

Having a faulty power lock switch in your vehicle can lead to an unsafe driving situation. If you notice a faulty power door lock switch in your vehicle, take it to a mechanic for diagnostics. Mechanics can diagnose power door lock switches by testing the electrical connections. If the switch does not transmit the correct levels of power to the door lock actuators, it may be time for a new switch.

Power door locks are controlled by a master switch in the driver’s side door panel. The switch typically fails first. If the switch is faulty, the driver may find that the door will unlock by pressing a button.

Power door locks can fail in three ways. The first and most common way is when the switch’s contacts are worn out. This can cause the switch to lock and unlock rapidly. Another cause is when the switch’s contacts become corroded. The switch can also be damaged from prolonged exposure to rain and snow.

When a door lock switch fails, the driver should stop driving and check the door lock mechanism. If the switch is faulty, the driver should listen for a clicking sound when he tries to open the door.

If the driver’s side switch is faulty, the driver may find that the passenger’s side lock switch is also faulty. The door switch is usually made from plastic. Plastic is prone to wear and corrosion.

If the driver’s side switch has corroded normally closed contacts, the driver may find that the switch on the passenger’s side will also lock and unlock. The switch can also be damaged from prolonged usage.

Mechanics should also check the power relay for voltage and ground. It is important to have the power relay receiving power from the switch and sending the voltage out.

Test if the actuator motor is the issue

Whether your power lock isn’t working, or you’re experiencing some strange noises, it’s a good idea to test if the actuator motor is the problem. If the motor isn’t producing enough current to function, it’s a good idea to replace it.

There are two main types of door locks: those that operate by motors, and those that operate with gears. Those with gears generally make more noise, while those with motors make less noise.

A typical actuator makes a short whirring sound when it’s in normal operation. When it starts to make a grinding sound, that’s a sign that it’s about to fail. If it’s making a louder noise, it’s a sign that the motor is worn out or that the gears are broken.

To check if the actuator motor is the problem, you’ll need to unplug the door lock from the door panel and test the wires. You can use a meter to determine the voltage going to the actuator. You can also use jumper wires to apply a 12 volt power source to the actuator.

If the test results show positive results, you’ll know the actuator is functioning correctly. If the test results are negative, the actuator motor is likely defective. Depending on the model of your vehicle, you may need to remove the door panel to access the actuator.

If the actuator motor is not the problem, you may have a wiring or circuit problem. The problem may be caused by debris or moisture entering the door lock actuator, or the mechanical links in the system may have become weak. You may also have a break in the electrical line. If you don’t know how to fix your door lock, it’s best to consult a professional.

Replace the old actuator motor

Whether you are looking to replace the actuator motor for power lock or are just trying to troubleshoot the problem, there are a few things you can check to help get the lock system working again. The most common complaint is that the power door lock function will not work. In order to fix this, you need to check the connection between the panel and the motor.

There are two ways to test this. The first is to connect a nine-volt battery to the motor. You may have to make a notch in the casing of the motor.

The second way is to connect a test lead to each of the motor’s contact points. You should also test the battery to see if it makes a sound.

The key to success is to make sure you use the correct test leads. If you are not confident in your skills, it may be better to call a professional to do the job for you.

If the test leads show a positive result, the door lock actuator is in good shape. However, you should be able to tell if your motor is working by listening to the motor when it is engaging the lock. If you can hear a noise, you may have a broken lock. If you don’t hear a noise, the motor may be bad or malfunctioning.

If you are looking to replace the actuator motor for power lock, it is a good idea to check for signs of rust. Rust can weaken the mechanical links that hold the door lock in place. It can also cause dust and debris to enter the actuator and interfere with its operation.

editor by CX 2023-11-24

China OEM China Sheet Metal OEM Factory Small Low Power Rack Mount Server power lock and window conversion kit

Product Description

General Description:

1. Frame:Welded frame, unassembled structure with precise craftsmanship;

2. Single Section,compatiblewith 19″standard equipment;

3. Front Door: Tempered glass front door with over 180 turning degree;

4. Side Panel: Removable side panel, easy to install and maintain (lock optional);

5. Cable Entry on the top cover and bottom panel with knock-out plate;

6. L-Shaped Mounting Profile, easy to adjustable on the mounting rail;

7. Fan cutout on the top cover ,easy to install fan;

8. Installing back panel,easy to fix on the wall;

9. Various accessories for optional;

FAQ:

1.Q:Are you a factory or trading company?

A: We are a Factory, Distributor and Trading Company.

2.Q:Where is your factory located? How can I visit there?

A:Our factory and office is located in HangZhou City, China.

You can fly to HangZhou airport or ZheJiang airport, from home or abroad,

Warmly welcome to visit us!

3.Q: Can you do OEM?

A: Yes, we can do OEM products. It’s no problem.

4.Q:How can I get some samples?

A:We are honored to offer you samples.

5.Q:How does your factory do regarding quality control?

A:Quality is priority.We always attach great importance to quality controlling for to the very end. Our factory has gained CE,ROHS,SGS authentication.

| Type: | Network Cabinet |

|---|---|

| Usage: | Network Integration System |

| Installation: | Wall-Mounted Cabinet |

| Fan Number: | 1 to 2 PCS Fans |

| Capacity: | 4u-27u |

| Certification: | CE, ISO, RoHS, SGS,TUV,BV |

| Samples: |

US$ 21/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Power Lock Actuator Problems

Having a power lock installed in your vehicle is an extremely usef”ul tool, allowing you to lock the doors while parked. Having a power lock in your car also allows you to unlock the doors when you want to leave, which is extremely useful when you have small children or pets in the vehicle.

Body controllers dictate the locking and unlocking of power door locks

Using the power door locks of your choice, it is possible to lock or unlock your vehicle without ever having to touch your keys. However, that isn’t the case for every driver. In fact, some motorists are so enthralled by their power door locks that they are oblivious to the fact that the doors are locked until they slam their brake pedal. The body controllers on the other hand take care of that problem – and many more – for you. It even manages to keep your interior lights on while you’re cruising down the highway. In short, the body controller is the best thing to have in your car. Moreover, it can be reprogrammed to do all of your power door locks in one fell swoop. A few years back, this was a feat in and of itself, but in this day and age of driverless cars, it has become a necessity.

The body controller is the brains behind the power door locks of your choice, as well as the vehicle security systems. It even manages to keep your interior illuminated even as you make a beeline for the nearest gas station. The body controller even keeps track of which doors are open and which are locked. It can also be used to remotely control other door locks via the same key fob or via a wireless remote, in the event you need to unlock a specific door. It even manages to do all this with the minimal intrusion to your wallet. And if you’re one of the lucky few, it even offers an onboard diagnostics center, a feature that many competing brands aren’t so keen on.

Actuator motors

Using the right parts from the right suppliers can ensure that your power lock actuator will last you a lifetime. The cost of replacement parts is a fraction of the cost of a new car. A new power lock actuator will give you the confidence that your family and your valuable possessions will be safe from the vagaries of life. The best part is that your car will be the envy of the neighborhood. After you’ve made the purchase, a few minutes of the requisite chitchat is all it will take to get the job done.

You’ll be well on your way to the happy ever after in no time. Taking the time to test the power door actuator may be well worth the time and the effort. After all, a new vehicle is an investment in your life, not to mention the resale value of your possessions. Unlike the old school, the power door actuator is located in the driver’s side of your vehicle and the power door is inaccessible from the front passenger door. You can even opt to have it mounted in the trunk for easy access during those emergency road trips. The power door actuator is a small but mighty machine. Besides, your family and your belongings are safe from the scoundrels in the back seat. Keeping your family safe and secure is important whether it’s a quick stop at the coffee shop or a day out at the beach. Getting the best power door actuator is the best way to keep your loved ones safe from the scoundrels in your vehicle. Having your car in the best condition possible can be the difference between getting a call or having a full night’s sleep.

Faulty switches

Having a faulty power lock switch in your vehicle can lead to an unsafe driving situation. If you notice a faulty power door lock switch in your vehicle, take it to a mechanic for diagnostics. Mechanics can diagnose power door lock switches by testing the electrical connections. If the switch does not transmit the correct levels of power to the door lock actuators, it may be time for a new switch.

Power door locks are controlled by a master switch in the driver’s side door panel. The switch typically fails first. If the switch is faulty, the driver may find that the door will unlock by pressing a button.

Power door locks can fail in three ways. The first and most common way is when the switch’s contacts are worn out. This can cause the switch to lock and unlock rapidly. Another cause is when the switch’s contacts become corroded. The switch can also be damaged from prolonged exposure to rain and snow.

When a door lock switch fails, the driver should stop driving and check the door lock mechanism. If the switch is faulty, the driver should listen for a clicking sound when he tries to open the door.

If the driver’s side switch is faulty, the driver may find that the passenger’s side lock switch is also faulty. The door switch is usually made from plastic. Plastic is prone to wear and corrosion.

If the driver’s side switch has corroded normally closed contacts, the driver may find that the switch on the passenger’s side will also lock and unlock. The switch can also be damaged from prolonged usage.

Mechanics should also check the power relay for voltage and ground. It is important to have the power relay receiving power from the switch and sending the voltage out.

Test if the actuator motor is the issue

Whether your power lock isn’t working, or you’re experiencing some strange noises, it’s a good idea to test if the actuator motor is the problem. If the motor isn’t producing enough current to function, it’s a good idea to replace it.

There are two main types of door locks: those that operate by motors, and those that operate with gears. Those with gears generally make more noise, while those with motors make less noise.

A typical actuator makes a short whirring sound when it’s in normal operation. When it starts to make a grinding sound, that’s a sign that it’s about to fail. If it’s making a louder noise, it’s a sign that the motor is worn out or that the gears are broken.

To check if the actuator motor is the problem, you’ll need to unplug the door lock from the door panel and test the wires. You can use a meter to determine the voltage going to the actuator. You can also use jumper wires to apply a 12 volt power source to the actuator.

If the test results show positive results, you’ll know the actuator is functioning correctly. If the test results are negative, the actuator motor is likely defective. Depending on the model of your vehicle, you may need to remove the door panel to access the actuator.

If the actuator motor is not the problem, you may have a wiring or circuit problem. The problem may be caused by debris or moisture entering the door lock actuator, or the mechanical links in the system may have become weak. You may also have a break in the electrical line. If you don’t know how to fix your door lock, it’s best to consult a professional.

Replace the old actuator motor

Whether you are looking to replace the actuator motor for power lock or are just trying to troubleshoot the problem, there are a few things you can check to help get the lock system working again. The most common complaint is that the power door lock function will not work. In order to fix this, you need to check the connection between the panel and the motor.

There are two ways to test this. The first is to connect a nine-volt battery to the motor. You may have to make a notch in the casing of the motor.

The second way is to connect a test lead to each of the motor’s contact points. You should also test the battery to see if it makes a sound.

The key to success is to make sure you use the correct test leads. If you are not confident in your skills, it may be better to call a professional to do the job for you.

If the test leads show a positive result, the door lock actuator is in good shape. However, you should be able to tell if your motor is working by listening to the motor when it is engaging the lock. If you can hear a noise, you may have a broken lock. If you don’t hear a noise, the motor may be bad or malfunctioning.

If you are looking to replace the actuator motor for power lock, it is a good idea to check for signs of rust. Rust can weaken the mechanical links that hold the door lock in place. It can also cause dust and debris to enter the actuator and interfere with its operation.

editor by CX 2023-11-23

China OEM Basics Manchester Entry Door Lever with Lock Matte Black power button lock out

Product Description

Product Description

| Item Name | Basics Manchester Entry Door Lever with Lock Matte Black |

| Item Code | QA-9435-ET |

| Door Lock Type | Fire proof steel Door Lock,Steel fire door Lock,Fire rated Metal door Lock, Hollow Metal Door Lock Fire proof steel Door Hanlde,Steel fire door Hanlde,Fire rated Metal door Hanlde, Hollow Metal Door Hanlde |

| Materials | Aluminum/Aluminium alloy |

| Size | Length 159 * Width 32 * Height 55 MM |

| Surface Color | Black/Gold/Gray |

| Handle Panel Color | Pure color,Wood grain,Stone grain,Fabric grain |

| Finish | Power coated,Spray coating,Spraying power,Power spraying |

| Advantage of BOGO door handle lock | 1. Suitable door thickness: 40mm-68mm |

| 2. Aluminum alloy beautiful appearance, good color and good corrosion resistance | |

| 3. Passed the UL NFPA BS CE EN AS…etc. test. | |

| Accessories | Include door handle, lock body, screws, keys (if necessary), installation instructions, with key or without key |

| Services | CAD Drawing Design, Color & Section sample |

| Application | Suitable for swing door, casement door, glass door, bathroom door, building project, house entrances, villas and warehouses. Etc |

| Package | Standard export carton with shipping mark, about 30SETS 31KGS 0.1CBM per carton |

Detailed Photos

Production workshop and lab

Packaging & Shipping

FAQ

Q:Are you a manufacturer or trading company?

A:Certanily dear,we are a manufacturer located in No.6, Science & Technolody West Road,Song Xia Industrial Park, Xihu (West Lake) Dis. District,HangZhou City,China.There is my pleasure welcome to visit us when you want for anytime.

Q:Do you provide samples? Is it free or extra?

A:Yes,we do.We advice you can pay the sample and freight charge first,which will be deducted from next order when you confirm.

Q:What time is the cargoes delivery time?

A:For sample can shipping anytime if in stock,for mass production is about 20-30 days after received the deposit.

Q:Which payment terms you can do that?

A:T/T, D/P, Western Union, L/C

Q:How about after-sales service?

A:If you have any questions, please feel free to contact us, bring product pictures or videos, and we will deal with them for you as soon as possible.

Please feel free to contact us for more questions!

| Material: | Aluminum Alloy |

|---|---|

| Type: | Key Lock |

| Style: | Modern |

| Shape: | Mortise Door Lock |

| Anti-theft Standard: | a/B/C |

| Part: | Lock |

| Samples: |

US$ 35/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to Diagnose and Replace a Bad Door Lock Actuator

Symptoms of a bad door lock actuator

Symptoms of a bad door lock actuator include strange noises when the lock is activated. The noise may be loud and it may also be intermittent. A bad actuator may also trigger an anti-theft alarm. If you experience any of these symptoms, it is time to find out what is causing the problem. There are several things that can cause your actuator to fail, and you may need to replace it in order to get your door locking system to work again.

First, you need to check to see if the lock is working correctly. This can be done by checking the power and the voltage to the actuator. The power to the actuator will be easier to determine than the voltage. In some cases, a blown fuse can indicate that the power is not reaching the actuator. If you suspect this is the case, you can use a power probe to apply 12 volts to the actuator.

You can also check for the door open warning light. If you see this light, you can check to see if the door lock actuator is triggering the alarm. If you don’t see the warning light, you might need to replace the actuator. In some cases, the door open warning light will be on even when you have closed the doors. This can be caused by debris in the mechanical linkage.

You can also test the voltage to the actuator by using jumper wires. If you don’t have jumper wires, you can use a Power Probe to apply 12 volts to the actuator. If the voltage is not correct, it is time to replace the actuator.

The door lock actuator is a motor-based device that engages the door lock when you press the lock button. It can be difficult to reach the mechanism, so you may have to remove the door panel to access it. If you can access the mechanism, you can inspect it for wear or other problems. You may need to replace the door lock actuator or the door lock assembly.

You may also hear a clicking sound when you use the power handle. This is one of the more common symptoms of a bad door lock actuator. The clicking sound may also be heard when you manually lock and unlock the door. In addition, a faulty actuator may result in the door to partially lock. This can lead to a false sense of binding.

Other symptoms of a bad door lock actuator include a loud buzzing sound during operation. This may be due to a damaged motor gear. It is important to check for any noises when replacing the actuator. The door lock actuator is part of an assembly, so you need to make sure that all of the parts are properly connected.

You may be able to replace the door lock actuator by removing the door panel, but you may also need to remove the door cover to access the mechanism. This can prevent debris from entering the door, but will also limit access to the inside of the door.

Troubleshooting a bad door lock switch

Having a door lock switch fail can be a nuisance. While there are no specific intervals for failure, a broken switch can be a sign of a faulty electrical contact. It can also lead to a stuck door and power window problems. Here are some tips to help you diagnose the problem and get your door lock working again.

The most important thing to do is determine the cause of the problem. This will prevent you from spending too much time or money pursuing the wrong solution. In order to determine the cause of a problem, you must perform a few tests. The first test to be performed is to examine the door lock switch. If it is not working, you will likely have to replace the entire switch assembly.

The second test to be performed is to check the power output. The power output of the switch can be determined by examining the voltage polarity of the electrical connector. You should see at least 12 V polarity to the connector when the switch is activated. If the power output is low, the switch is most likely faulty. The voltage polarity can be checked with a volt meter. If you cannot find a volt meter, you may have to visit a professional mechanic to have the wiring and connections of the switch checked.

The third test to be performed is to determine the best way to operate the switch. This can be done by experimenting with various options to see what works best. It is also a good idea to note the results of each operation. It is also a good idea to listen for a click when the door lock is energized. If there is no clicking, this could indicate that the switch is faulty.

The best way to test the power output of the switch is to take a look at the voltage polarity of the electrical connector. If the switch is working, the voltage should be toggling from one side to the other. You should see a slight change in the manual door lock knob if the switch is working. If the switch is faulty, the knob may be stuck in a position. The knob may be stuck in an unusable position.

The best way to test the door lock switch is by examining the door lock assembly. The assembly consists of a cluster of screws and wires that are secured together. This assembly must be inspected for any signs of damage. It may also be necessary to replace the door cluster. You should also make sure that the door panel is in place. This is a fairly involved process that requires you to remove the door panel and test the switch for continuity. You should also make sure that the wiring harness is connected in the same manner as before. If you have to remove the door panel, make sure to secure it back in place.

Taking care of a blown fuse

Taking care of a blown fuse in a power lock is essential to maintaining the integrity of your vehicle’s electrical system. Blown fuses stop the flow of electrical power and can cause damage to components such as the engine, power windows, and other parts of your vehicle. When a fuse blows, you will need to replace it with a new one. If you are not confident in replacing a fuse on your own, you should contact a professional mechanic or an electrician.

Blown fuses are usually caused by overloading a circuit. This causes the metal ribbon on the fuse to melt and cause the fuse to blow. This can happen due to a number of reasons, including a problem with an appliance or a component, or a momentary current surge. If the underlying problem is not rectified, the fuse will continue to blow.

If you have a fuse that has blown, the first step is to turn off the power. You should also unplug any electrical appliances or items that are connected to the tripped circuit. It is important to remove the fuse from its housing before you begin replacing it.

Before you begin replacing a fuse, you should use a multimeter to check the resistance of the fuse. If the resistance is high, you will need to replace the fuse. If the resistance is low, it is likely that the fuse is still working. You can test the resistance of the fuse by using the ohmmeter setting on your multimeter.

A blown fuse may cause a problem with the radio, power locks, interior lights, and other components in your vehicle. The circuit breaker may also be tripped, causing you to lose power. If you have lost power, you should remove any jewelry and other electrical devices that you have plugged into the area where you are having problems. If your equipment is still not working after you have replaced the fuse, you may have a more serious problem.

The fuse box for your vehicle is located underneath the steering column. You can usually access it by lifting the lid of the fuse box. You will need a flat-head screwdriver or needle-nose pliers to open the lid. You can find a fuse box diagram in your owner’s manual. Having a diagram will make it easier to locate the fuse box. You may also want to consult with a mobile mechanic, as they come to your home or office for easy access.

Blown fuses are a common occurrence. They are easy to repair, but should be replaced when they are damaged. You can purchase fuses from any auto parts store. Most newer vehicles allow you to remove the fuse box lid by hand. If you want to do it yourself, you can find instructions for removing fuses from your owner’s manual.

Blown fuses can be very dangerous if you don’t know what you are doing. It is recommended that you never attempt to work on your electrical system without proper safety equipment and supervision. If you do not have access to an electrician, you should unplug all electrical appliances in the affected area and call a qualified electrician.

editor by CX 2023-11-21

China OEM Investment Casting Stainless Steel OEM Bracket Parts power lock dead space

Product Description

| Port: | ZheJiang or HangZhou, China |

| Production Capacity: | 200tons /Month |

| Payment Terms: | L/C, T/T |

| Casting Method: | Thermal Gravity Casting |

| Process: | Lost Wax Casting |

| Molding Technics: | Pressure Casting |

| Application: | Machinery Parts |

| Material: | Stainless Steel |

| Surface Preparation: | Sand Blast |

Basic Info

Surface Roughness: Ra1.6

Machining Tolerance: +/-0.01mm

Standard: GB

Certification: ISO 9001:2008 , TS16949

Payment Terms: T/T

MOQ: 500 Pieces

Lead Time: 50 Days After Deposit

Service: OEM /ODM as Customers drawings

Trademark: HX

Transport Package: Wooden Carton

Specification: customized size customers′drawing

Origin: HangZhou, China

| Description | CUSTOM MADE PRECISION CASTINGS |

| Material | (1)Stainless steel, SS304, SS316, SS316L, etc (2)carbon steel,CB1571, 1571, 1030, etc. (3)Alloy steel, ASTM A48, CK45, 1.7218-25CrMo4 , etc |

| Standard | ISO ,DIN, AISI, ASTM, BS, JIS, etc. |

| Size | Available in all sizes or as customer’s drawings |

| Certification | ISO9001:2008 , TS16949 |

| Application | Industrial parts,Machinery parts,construction parts,valve parts, pump parts, impeller parts, train,craft,hydraulic pressure, Agriculturalmachinery,Marine hardware,Auto parts,electric power fittings,food machinery,harness fittings,machinery parts |

| Weight Range | 0.01kg-200kg |

| Machining precision | ±0.01mm |

| Surface Treatment | Heat Treatment, Polishing, Plating, Machining, shot, sand blasting, zinc plated,e-coating, etc. |

| Process | Investment casting, Lost wax casting process, silicasol casting process |

| Production Application | Metal parts, Mechanical parts, Marine Hardware, Electric power fitting, Construction parts, Pipe Fitting, Hardware, Auto parts, Valve parts, pump parts, impeller parts, Industrial parts, Agricultural machinery etc |

| CNC and MC machining | Three coordinate measurement machine for testing. |

| Service | To chart to sample production;OEM / ODM |

| Packing details | Wood or carton packages as per your demands |

| MOQ | 500 pieces (Small order is accepted) |

FAQ:

1. How to contact with your company?

2 .What does your company need to submit a quotation?

Drawing or sample, together with relevant information, such as quantity, weight, material.

3. Which kind of format of the drawing?

PDF, IGS, DWG, STEP, etc

4 . What if we do not have a drawing?

We can duplicate your sample and make drawing for your confirmation.

5. How soon before I get a sample?

weeks for mold and sample, 3-7 days for express.

6.Where does your company locate?

HangZhou City, ZHangZhoug province, China, which is near ZheJiang and HangZhou.

8.Can I visit your company?

Yes, sure, welcome your visit anytime. We will book hotel and pick you up from airport.

9. How can we quote for you?

As our factory only supply OEM service(custom service)

Please send us enquiry by email, with all the technical drawings you have, with all of your requirements,

such as material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

It is also best if you can provide a sample, we can also quote depends on the sample.

| Usage: | Projector Bracket, Shelf Bracket |

|---|---|

| Material: | Stainless Steel |

| Style: | New Classical |

| Structure: | Single-side Bracket |

| Manufacturing Arts: | Metal |

| Adjusted: | Unadjustable |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Using a Power Lock

Using a power lock in your vehicle allows you to lock the doors without having to take your hands off the wheel. It is also great for front passengers to use.

Actuator

Among the most common features on any vehicle are power door locks. These locks work by turning a gear mechanism and lock or unlock the door. The gear mechanism is made of an electric motor and spur gears.

Power door lock actuators are critical to the operation of a power door lock feature. When a power door lock actuator fails, it disables the power door lock feature.

The most common complaint about a power door lock actuator is that it locks and unlocks intermittently. This may be due to a problem with the wiring or circuits.

Some symptoms of a faulty power door lock actuator are noises coming from inside the door. For example, when a motor is not turning, it will make a loud “clunk” sound. When a motor is working properly, there will be little or no noise.

A faulty power door lock actuator may also cause a car to lock and unlock randomly. This can happen due to a faulty circuit or circuits wearing out.

Alternatively, a faulty actuator may be the result of a water leak in the door. If this is the case, the water may enter the door lock actuator and cause it to malfunction. Fortunately, there are a number of ways to check the condition of your actuator and fix any problems.

Body controller

Almost all modern day cars have some form of power lock, but only a select few have a body controller to boot. The fancy name is the electronic control unit, but the acronym ECU stands for Electronic Control Unit, or ECU for short. The ECU is responsible for coordinating the myriad electronic components that are dotted throughout your vehicle’s occupant compartment. It also controls things like power windows and the air conditioning. You can see the ECU in action by glancing at your dashboard. It’s a small and power-packed box, but a discerning eye will spot a few stragglers amongst the more mundane tasks. The ECU is also responsible for ensuring the safety of passengers by ensuring that the doors remain unlocked until a specified interval.

The ECU’s lesser known cousins, like the power door lock, are only responsible for a few of the more mundane tasks. Aside from the usual suspects, the ECU also manages the power mirrors and the power windows, albeit on a less than optimal schedule. A faulty ECU isn’t quite as funky as it sounds, and can be rectified by a trip to the local mechanic. If you’re not a mechanic, you’ll likely be able to remedy the situation with a simple door lock replacement.

Check for broken wires

Occasionally, you will need to check for broken wires when using a power lock. Having a broken wire will require you to repair it, or replace it with a new one. However, this process can be quite difficult, as it is hard to reach the motor. If you are unsure what wires are connected to your vehicle, you should consult a wiring diagram. If you do not have a diagram, you can also use a multimeter to check for continuity across all wires. However, a multimeter is not enough to check for broken wires. You will also need rubber gloves to do this safely.

To check for broken wires, first make sure you have access to the wires that are in the lock motor. These are usually located near the plug on the door frame. If you can’t reach them, you can use jumper wires to connect the actuator to the 12 volt power supply and test it for power. If this does not work, you will need to remove the lock motor from its electronic control board and check for a broken wire harness. However, if this is not possible, you can use a Power Probe to apply 12 volts to the actuator.

editor by CX 2023-11-14

China Best Sales Elastic Hook & Loop Tape with Buckle Lock power lock bushing

Product Description

Elastic Hook & Loop Tape with Buckle Lock

Product Feature

Seal Specification

| Model NO.: | Reusable Hook & Loop Tape with Buckle | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Type: | Hook & Loop Tape; | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material: | 1 sdyingli