Product Description

Product Description:

1. This series’ wheel chassis uses the 2571 newest updated system which assimilated mature technologies from many domestic brands. More reasonable structure minimums the malfunction rate in the process of using.

2. Four-stroke engines with high torque reserve. Engines are from YTO,Xinchai, Xichai,Laidong and Quanchai.

3. (4+1)×2 transmission structure with 8F +2R gears. Eight forward gears and 2 rear gears

4. Equip with double speed of PTO shaft 540/720 rpm. Adapted to different field type.

5. Adopt full hydraulic steering, independent fuel tank, easy operating and high mobility.

6. Adjustable front and rear tracks meet agricultural needs of different areas. Extra-large water tank and high capacity maintenance-free battery make the machine with best heat-dispersion and starting performance.

7. Steering system uses orbit hydrostatic steering gear with rotary valve. Flexible to operate with a more reliable and stable performance.

8. Differential lock prevent rear wheels skidding when climbing, operating in paddy land and rainy weather.

9. Optional Equipment: single or double hydraulic output system, air brake, side shift, strong hydraulic lifter, streamlined hood, wheel guards, different size tires.

Priduct picture

| Model | TK404E | TK454E | TK504E | TK554E | TK604E | ||

| Type | 4×4 Wheeled Type | 4×4 Wheeled Type | 4×4 Wheeled Type | 4×4 Wheeled Type | 4×4 Wheeled Type | ||

| Dimensions of Tractor (mm) |

Length | 3340 | 3340 | 3515 | 3515 | 3515 | |

| Width | 1510 | 1510 | 1510 | 1510 | 1510 | ||

| Height | 2571 | 2571 | 2571 | 2571 | 2571 | ||

| Tread | Front Wheel | 1200 | 1200 | 1200 | 1200 | 1200 | |

| Rear Wheel | 1200 | 1200 | 1200 | 1200 | 1200 | ||

| Wheel Base | 1800 | 1800 | 1920 | 1920 | 1920 | ||

| Min. Ground Base | 360(the bottom of front axle) | 360(the bottom of front axle) | 360(the bottom of front axle) | 360(the bottom of front axle) | 360(the bottom of front axle) | ||

| Min. Usage Mass(kg) | 1590 | 1510 | 1760 | 1760 | 1760 | ||

| Engine | Model | Laidong 4L23BT | Laidong 490 | Laidong 4L100 | Laidong 4100 | weichai | |

| Type | Vertical, water cooled and 4-stroke | Vertical, water cooled and 4-stroke | Vertical, water cooled and 4-stroke | Vertical, water cooled and 4-stroke | Vertical, water cooled and 4-stroke | ||

| Rated Power(kw) | 29.4 | 33.1 | 36.8 | 40.44 | 44.1 | ||

| Rated Rev.(r/min) | 2400 | 2400 | 2400 | 2400 | 2400 | ||

| Fuel | Diesel Oil | Diesel Oil | Diesel Oil | Diesel Oil | Diesel Oil | ||

| Tire | Front Wheel | 6.0-16 | 6.0-16 | 6.0-16 | 6.0-16 | 6.0-16 | |

| Rear Wheel | 9.5-24 | 9.5-24 | 9.5-24 | 9.5-24 | 9.5-24 | ||

| Clutch | Dry-friction,single stage or Dry-friction,Two Stage | Dry-friction,single stage or Dry-friction,Two Stage | Dry-friction,single stage or Dry-friction,Two Stage | Dry-friction,single stage or Dry-friction,Two Stage | Dry-friction,single stage or Dry-friction,Two Stage | ||

| Steering | Hydraulic type | Hydraulic type | Hydraulic type | Hydraulic type | Hydraulic type | ||

| Transmission Box | two shafts, (4+1)×2 composed | two shafts, (4+1)×2 composed | two shafts, (4+1)×2 composed | two shafts, (4+1)×2 composed | two shafts, (4+1)×2 composed | ||

| Suspension Type | Post Positioned Tri-point Suspension Catalogue I | Post Positioned Tri-point Suspension Catalogue I | Post Positioned Tri-point Suspension Catalogue I | Post Positioned Tri-point Suspension Catalogue I | Post Positioned Tri-point Suspension Catalogue I | ||

| PTO | Type and Rev.(r/min) | Post-position, non-independent, 720/850 |

Post-position, non-independent, 720/850 |

Post-position, non-independent, 720/850 |

Post-position, non-independent, 720/850 |

Post-position, non-independent, 720/850 |

|

| Spline Size | I35 Rectangle Spline with 6 teeth | I35 Rectangle Spline with 6 teeth | I35 Rectangle Spline with 6 teeth | I35 Rectangle Spline with 6 teeth | I35 Rectangle Spline with 6 teeth | ||

Standard Equipments:

Engine,4 Cylinders,8+2 Gear Shift,With Dual-Stage Clutch,Power Steering,Trailer outlet,

protection plate,Tires:8.3-24/14.9-30,hand throttle wire ,4×4 Wheel Drive,3-Point Linkage,

Rear PTO 540/760, Color follow your need.

Options:

Cab,Canopy,Air Brake,Tilting Draw Bar, Front end loader,backhoe

You can also choose any tools

Packaging & Delivery:

FCL&LCL

Company Information:

Telake (HangZhou) Agricultural equipment Co., Ltd. mainly produces medium and large horsepower wheeled tractors and supporting various agricultural machinery and tools. The main products of the company cover all kinds of wheeled tractors with 25 horsepower to 260 horsepower, and the corresponding agricultural machinery and tools. At present, the products are sold all over the country and more than 10 countries and regions abroad. Among them, the medium-horsepower wheeled tractors are in the leading position in the industry in terms of technology and quality. The company has strong technical force, strong development ability, perfect detection means and complete post-sale service system.

OUR SERVICES

1. Free tool box and free easy damage parts.

2. Warranty time: 18 months after the goods delivery your port.

3. Delivery time: 20 days for 1 container.

4.8 units in 1 20FT container. 16units in 1 40FT container.

5. Every color we can do for you.

6. We can do the tractor with your logo in your order. (It Is Free)

7. Payment term: T/T30% in advance, 70% T/T after the shipping, or L/C at sight.

| Warranty: | 1year |

|---|---|

| Type: | Wheel Tractor |

| Usage: | Farm Tractor, Garden Tractor, Lawn Tractor |

| Certification: | ISO, CE, EPA, CCC, ISO/TS16949, EEC, XQC |

| Drive Wheel: | 4WD |

| Emission Standard: | Euro II |

| Samples: |

US$ 3920/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to Diagnose and Replace a Bad Door Lock Actuator

Symptoms of a bad door lock actuator

Symptoms of a bad door lock actuator include strange noises when the lock is activated. The noise may be loud and it may also be intermittent. A bad actuator may also trigger an anti-theft alarm. If you experience any of these symptoms, it is time to find out what is causing the problem. There are several things that can cause your actuator to fail, and you may need to replace it in order to get your door locking system to work again.

First, you need to check to see if the lock is working correctly. This can be done by checking the power and the voltage to the actuator. The power to the actuator will be easier to determine than the voltage. In some cases, a blown fuse can indicate that the power is not reaching the actuator. If you suspect this is the case, you can use a power probe to apply 12 volts to the actuator.

You can also check for the door open warning light. If you see this light, you can check to see if the door lock actuator is triggering the alarm. If you don’t see the warning light, you might need to replace the actuator. In some cases, the door open warning light will be on even when you have closed the doors. This can be caused by debris in the mechanical linkage.

You can also test the voltage to the actuator by using jumper wires. If you don’t have jumper wires, you can use a Power Probe to apply 12 volts to the actuator. If the voltage is not correct, it is time to replace the actuator.

The door lock actuator is a motor-based device that engages the door lock when you press the lock button. It can be difficult to reach the mechanism, so you may have to remove the door panel to access it. If you can access the mechanism, you can inspect it for wear or other problems. You may need to replace the door lock actuator or the door lock assembly.

You may also hear a clicking sound when you use the power handle. This is one of the more common symptoms of a bad door lock actuator. The clicking sound may also be heard when you manually lock and unlock the door. In addition, a faulty actuator may result in the door to partially lock. This can lead to a false sense of binding.

Other symptoms of a bad door lock actuator include a loud buzzing sound during operation. This may be due to a damaged motor gear. It is important to check for any noises when replacing the actuator. The door lock actuator is part of an assembly, so you need to make sure that all of the parts are properly connected.

You may be able to replace the door lock actuator by removing the door panel, but you may also need to remove the door cover to access the mechanism. This can prevent debris from entering the door, but will also limit access to the inside of the door.

Troubleshooting a bad door lock switch

Having a door lock switch fail can be a nuisance. While there are no specific intervals for failure, a broken switch can be a sign of a faulty electrical contact. It can also lead to a stuck door and power window problems. Here are some tips to help you diagnose the problem and get your door lock working again.

The most important thing to do is determine the cause of the problem. This will prevent you from spending too much time or money pursuing the wrong solution. In order to determine the cause of a problem, you must perform a few tests. The first test to be performed is to examine the door lock switch. If it is not working, you will likely have to replace the entire switch assembly.

The second test to be performed is to check the power output. The power output of the switch can be determined by examining the voltage polarity of the electrical connector. You should see at least 12 V polarity to the connector when the switch is activated. If the power output is low, the switch is most likely faulty. The voltage polarity can be checked with a volt meter. If you cannot find a volt meter, you may have to visit a professional mechanic to have the wiring and connections of the switch checked.

The third test to be performed is to determine the best way to operate the switch. This can be done by experimenting with various options to see what works best. It is also a good idea to note the results of each operation. It is also a good idea to listen for a click when the door lock is energized. If there is no clicking, this could indicate that the switch is faulty.

The best way to test the power output of the switch is to take a look at the voltage polarity of the electrical connector. If the switch is working, the voltage should be toggling from one side to the other. You should see a slight change in the manual door lock knob if the switch is working. If the switch is faulty, the knob may be stuck in a position. The knob may be stuck in an unusable position.

The best way to test the door lock switch is by examining the door lock assembly. The assembly consists of a cluster of screws and wires that are secured together. This assembly must be inspected for any signs of damage. It may also be necessary to replace the door cluster. You should also make sure that the door panel is in place. This is a fairly involved process that requires you to remove the door panel and test the switch for continuity. You should also make sure that the wiring harness is connected in the same manner as before. If you have to remove the door panel, make sure to secure it back in place.

Taking care of a blown fuse

Taking care of a blown fuse in a power lock is essential to maintaining the integrity of your vehicle’s electrical system. Blown fuses stop the flow of electrical power and can cause damage to components such as the engine, power windows, and other parts of your vehicle. When a fuse blows, you will need to replace it with a new one. If you are not confident in replacing a fuse on your own, you should contact a professional mechanic or an electrician.

Blown fuses are usually caused by overloading a circuit. This causes the metal ribbon on the fuse to melt and cause the fuse to blow. This can happen due to a number of reasons, including a problem with an appliance or a component, or a momentary current surge. If the underlying problem is not rectified, the fuse will continue to blow.

If you have a fuse that has blown, the first step is to turn off the power. You should also unplug any electrical appliances or items that are connected to the tripped circuit. It is important to remove the fuse from its housing before you begin replacing it.

Before you begin replacing a fuse, you should use a multimeter to check the resistance of the fuse. If the resistance is high, you will need to replace the fuse. If the resistance is low, it is likely that the fuse is still working. You can test the resistance of the fuse by using the ohmmeter setting on your multimeter.

A blown fuse may cause a problem with the radio, power locks, interior lights, and other components in your vehicle. The circuit breaker may also be tripped, causing you to lose power. If you have lost power, you should remove any jewelry and other electrical devices that you have plugged into the area where you are having problems. If your equipment is still not working after you have replaced the fuse, you may have a more serious problem.

The fuse box for your vehicle is located underneath the steering column. You can usually access it by lifting the lid of the fuse box. You will need a flat-head screwdriver or needle-nose pliers to open the lid. You can find a fuse box diagram in your owner’s manual. Having a diagram will make it easier to locate the fuse box. You may also want to consult with a mobile mechanic, as they come to your home or office for easy access.

Blown fuses are a common occurrence. They are easy to repair, but should be replaced when they are damaged. You can purchase fuses from any auto parts store. Most newer vehicles allow you to remove the fuse box lid by hand. If you want to do it yourself, you can find instructions for removing fuses from your owner’s manual.

Blown fuses can be very dangerous if you don’t know what you are doing. It is recommended that you never attempt to work on your electrical system without proper safety equipment and supervision. If you do not have access to an electrician, you should unplug all electrical appliances in the affected area and call a qualified electrician.

editor by CX 2023-10-26

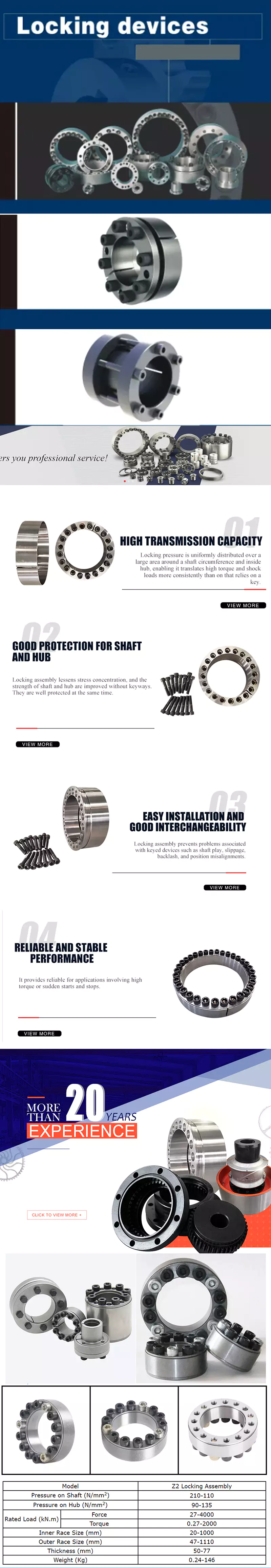

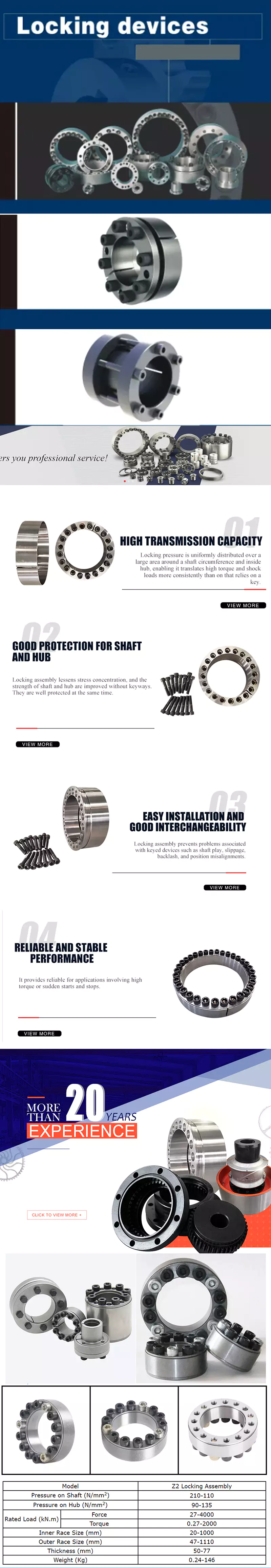

China Textile Machinery Transmission Parts Z2-400X495 Power Lock power lock dead space

Item Description

Description of Z2 Locking Device

Most broadly employed product with full sizes

Substantial torque transmission

Soon after tightening, the hub can go axially

Parameter of Z2 Locking Device

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z2-400X495 Locking Assembly |

| Type: | Z2-400X495 |

| Iner Size(mm): | 400 |

###

| Customization: |

Available

|

|---|

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z2-400X495 Locking Assembly |

| Type: | Z2-400X495 |

| Iner Size(mm): | 400 |

###

| Customization: |

Available

|

|---|

How to Diagnose and Replace a Bad Door Lock Actuator

Symptoms of a bad door lock actuator

Symptoms of a bad door lock actuator include strange noises when the lock is activated. The noise may be loud and it may also be intermittent. A bad actuator may also trigger an anti-theft alarm. If you experience any of these symptoms, it is time to find out what is causing the problem. There are several things that can cause your actuator to fail, and you may need to replace it in order to get your door locking system to work again.

First, you need to check to see if the lock is working correctly. This can be done by checking the power and the voltage to the actuator. The power to the actuator will be easier to determine than the voltage. In some cases, a blown fuse can indicate that the power is not reaching the actuator. If you suspect this is the case, you can use a power probe to apply 12 volts to the actuator.

You can also check for the door open warning light. If you see this light, you can check to see if the door lock actuator is triggering the alarm. If you don’t see the warning light, you might need to replace the actuator. In some cases, the door open warning light will be on even when you have closed the doors. This can be caused by debris in the mechanical linkage.

You can also test the voltage to the actuator by using jumper wires. If you don’t have jumper wires, you can use a Power Probe to apply 12 volts to the actuator. If the voltage is not correct, it is time to replace the actuator.

The door lock actuator is a motor-based device that engages the door lock when you press the lock button. It can be difficult to reach the mechanism, so you may have to remove the door panel to access it. If you can access the mechanism, you can inspect it for wear or other problems. You may need to replace the door lock actuator or the door lock assembly.

You may also hear a clicking sound when you use the power handle. This is one of the more common symptoms of a bad door lock actuator. The clicking sound may also be heard when you manually lock and unlock the door. In addition, a faulty actuator may result in the door to partially lock. This can lead to a false sense of binding.

Other symptoms of a bad door lock actuator include a loud buzzing sound during operation. This may be due to a damaged motor gear. It is important to check for any noises when replacing the actuator. The door lock actuator is part of an assembly, so you need to make sure that all of the parts are properly connected.

You may be able to replace the door lock actuator by removing the door panel, but you may also need to remove the door cover to access the mechanism. This can prevent debris from entering the door, but will also limit access to the inside of the door.

Troubleshooting a bad door lock switch

Having a door lock switch fail can be a nuisance. While there are no specific intervals for failure, a broken switch can be a sign of a faulty electrical contact. It can also lead to a stuck door and power window problems. Here are some tips to help you diagnose the problem and get your door lock working again.

The most important thing to do is determine the cause of the problem. This will prevent you from spending too much time or money pursuing the wrong solution. In order to determine the cause of a problem, you must perform a few tests. The first test to be performed is to examine the door lock switch. If it is not working, you will likely have to replace the entire switch assembly.

The second test to be performed is to check the power output. The power output of the switch can be determined by examining the voltage polarity of the electrical connector. You should see at least 12 V polarity to the connector when the switch is activated. If the power output is low, the switch is most likely faulty. The voltage polarity can be checked with a volt meter. If you cannot find a volt meter, you may have to visit a professional mechanic to have the wiring and connections of the switch checked.

The third test to be performed is to determine the best way to operate the switch. This can be done by experimenting with various options to see what works best. It is also a good idea to note the results of each operation. It is also a good idea to listen for a click when the door lock is energized. If there is no clicking, this could indicate that the switch is faulty.

The best way to test the power output of the switch is to take a look at the voltage polarity of the electrical connector. If the switch is working, the voltage should be toggling from one side to the other. You should see a slight change in the manual door lock knob if the switch is working. If the switch is faulty, the knob may be stuck in a position. The knob may be stuck in an unusable position.

The best way to test the door lock switch is by examining the door lock assembly. The assembly consists of a cluster of screws and wires that are secured together. This assembly must be inspected for any signs of damage. It may also be necessary to replace the door cluster. You should also make sure that the door panel is in place. This is a fairly involved process that requires you to remove the door panel and test the switch for continuity. You should also make sure that the wiring harness is connected in the same manner as before. If you have to remove the door panel, make sure to secure it back in place.

Taking care of a blown fuse

Taking care of a blown fuse in a power lock is essential to maintaining the integrity of your vehicle’s electrical system. Blown fuses stop the flow of electrical power and can cause damage to components such as the engine, power windows, and other parts of your vehicle. When a fuse blows, you will need to replace it with a new one. If you are not confident in replacing a fuse on your own, you should contact a professional mechanic or an electrician.

Blown fuses are usually caused by overloading a circuit. This causes the metal ribbon on the fuse to melt and cause the fuse to blow. This can happen due to a number of reasons, including a problem with an appliance or a component, or a momentary current surge. If the underlying problem is not rectified, the fuse will continue to blow.

If you have a fuse that has blown, the first step is to turn off the power. You should also unplug any electrical appliances or items that are connected to the tripped circuit. It is important to remove the fuse from its housing before you begin replacing it.

Before you begin replacing a fuse, you should use a multimeter to check the resistance of the fuse. If the resistance is high, you will need to replace the fuse. If the resistance is low, it is likely that the fuse is still working. You can test the resistance of the fuse by using the ohmmeter setting on your multimeter.

A blown fuse may cause a problem with the radio, power locks, interior lights, and other components in your vehicle. The circuit breaker may also be tripped, causing you to lose power. If you have lost power, you should remove any jewelry and other electrical devices that you have plugged into the area where you are having problems. If your equipment is still not working after you have replaced the fuse, you may have a more serious problem.

The fuse box for your vehicle is located underneath the steering column. You can usually access it by lifting the lid of the fuse box. You will need a flat-head screwdriver or needle-nose pliers to open the lid. You can find a fuse box diagram in your owner’s manual. Having a diagram will make it easier to locate the fuse box. You may also want to consult with a mobile mechanic, as they come to your home or office for easy access.

Blown fuses are a common occurrence. They are easy to repair, but should be replaced when they are damaged. You can purchase fuses from any auto parts store. Most newer vehicles allow you to remove the fuse box lid by hand. If you want to do it yourself, you can find instructions for removing fuses from your owner’s manual.

Blown fuses can be very dangerous if you don’t know what you are doing. It is recommended that you never attempt to work on your electrical system without proper safety equipment and supervision. If you do not have access to an electrician, you should unplug all electrical appliances in the affected area and call a qualified electrician.

editor by czh 2022-12-20

china near me shop Sk3-035 Stainless Steel Machinery Draw Latch Cabinet Toggle Hasp Lock manufacturers

Item Description

SK3-571H-5 Robot adjustable vertical Rapid Launch toggle Clamps

|

Product Identify |

SKK3-571H-5 Robot adjustable vertical Rapid Release toggle Clamps |

|

Content |

Stainless Metal(SUS304) |

|

Complete |

Vivid Chrome Plated/ Black Painted |

|

Sort |

Toggle Clamp |

|

Purposes |

Cabinet, CZPT vehicle Particular motor vehicle Soundproof generator |

|

Supply |

Airfreight CZPT CZPT |

|

Merchandise N.W(g) |

65g |

|

Remarks

|

Appropriate for remaining and right facet opening. |

two. Drawing and picture

three. Firm information :

ShangKun Positive aspects:

1.The origin from the world manufacturing unit of Xihu (West CZPT ) Dis.Guan

two. Factory immediate income and shorten the intermediate hyperlink

3.Safety shipping. There are a plenty of inventory, quick manufacturing cycle, excellent logistics and delivery on time.

4.Top quality assurance for 1 calendar year. There are large high quality solution, perfect services and favorable price tag to assurance the product’s high quality for 1year

five. Brand name packaging. Using the official standardization bundle to defend the product’s quality

Manufacturer Certification:

1.High quality administration technique certification certificate

2. Zinc alloy certificate of environmental safety

three.Plastic certificate of environmental security

4.Stainless metal certification of environmental safety

5. Patent certification of new utility

6.Credentials of CZPT -Government-Operate science and engineering company

Deals:

Plastic Bag+Regular Colour Box + Carton

Logistics:

We promise to provide products on time

| Design ideas | ||||||||||

| Shang Kun industrial hardware is a skilled factory for hinge and latch, the high quality of CZPT product is really very good and the price is affordable, the entire products design and style aesthetic generous , With CZPT own R&D crew and strong potential of materials sourcing, we are often competent for most of prerequisite from CZPT ers. We have recognized a rigid high quality handle technique in manufacturing facility, so,it is the best items for your choice. | ||||||||||

| Good quality Control | ||||||||||

| All the content is presented by specialized supplies. so we do not cut corners, the excess weight is natural, and the hinge’s operating daily life is extremely CZPT , so it has a very good worth. We can offer a lot of sorts of distinct content quality sequence products for your chose. | ||||||||||

| Service | ||||||||||

| *Customized emblem: Satisfactory | ||||||||||

| *Shifting on content, mould, form: Acceptable | ||||||||||

| *Produce on Artwork and Sketch: Suitable | ||||||||||

| *Packing: Acceptable | ||||||||||

| *Sample: Acceptable | ||||||||||

| MOQ | ||||||||||

| Kindly, as to the smallest quantity of purchase, we welcome consumers distinct dimensions at the very least, at this phase and thus at present we have no rigid restrict on MOQ. |

Our factory:

Our items:

FAQ:

1. Are you a manufacturing unit ?

Sure, we are expert maker and specialising in substantial quality lock a lot more than 10 several years

two. Can you offer you me sample if we want?

Of coure we can, but I think it will be greater to verify the price very first, as you acknowledge my price tag we’ll provide you

my sample for reference

three. What’s your packing?

PP bag+ internal box+ carton

four. What is actually your payment ?

thirty% deposit , 70% harmony just before cargo by T/T or Paypal

five. What is your shipping and delivery time ?

fifteen-30days right after getting the buy

six. Can we check out your factory?

It really is CZPT enjoyment, just inform us just before you coming, we will give you some info about how to get there

four. Contact us :

china manufacturer manufacturer sales Locking Assembly Standardlight Machinery Keyless Shaft Power Lock Z3 manufacturers

Item Description

SC Transmission Locking Assembly Regular

Light CZPT ry Keyless Shaft CZPT Lock Z3

Item Description

Z2 CZPT LOCK

Merchandise Parameters

Energy LOCK

| 12.nine | |||||||||||||

| mm | Ft | Mt | |||||||||||

| d | D | L | L1 | L2 | KN | M1 | N/mm2 | N/mm2 | N.m | d1 | n | kg | |

| Z3-twenty | twenty | 47 | 37 | 31 | 21.seven | 30 | .3 | 287 | ninety | 17 | M6 | 4 | .29 |

| Z3-22 | 22 | forty seven | .33 | 260 | 90 | .27 | |||||||

| Z3-25 | twenty five | fifty | 35 | .44 | 287 | 106 | 5 | .3 | |||||

| Z3-28 | 28 | 55 | 35 | .forty nine | 256 | ninety six | .36 | ||||||

| Z3-thirty | 30 | fifty five | 35 | .53 | 239 | 96 | .34 | ||||||

| Z3-35 | 35 | 60 | forty five | .eighty one | 246 | 106 | .38 | ||||||

| Z3-forty | forty | 65 | forty five | .ninety four | 215 | 98 | .41 | ||||||

| Z3-45 | forty five | seventy five | 46 | 38 | 25.3 | eighty | 1.86 | 283 | 134 | 41 | M8 | 6 | .seven |

| Z3-fifty | fifty | 80 | eighty | 2.07 | 255 | 126 | .seventy six | ||||||

| Z3-55 | 55 | eighty five | ninety | two.fifty four | 270 | 138 | 7 | .82 | |||||

| Z3-sixty | sixty | 90 | 90 | two.seventy seven | 247 | a hundred thirty | .88 | ||||||

| Z3-sixty five | sixty five | ninety five | a hundred and five | three.fifty eight | 261 | 141 | eight | .94 | |||||

| Z3-70 | 70 | a hundred and ten | 60 | 50 | 33.4 | a hundred and forty | five.1 | 244 | 128 | eighty three | M10 | 7 | two.one |

| Z3-seventy five | seventy five | 115 | one hundred forty | five.forty six | 228 | 119 | two.two | ||||||

| Z3-eighty | eighty | a hundred and twenty | 140 | 5.85 | 214 | 112 | two.3 | ||||||

| Z3-85 | eighty five | a hundred twenty five | 175 | seven.forty five | 230 | 129 | 8 | 2.4 | |||||

| Z3-90 | ninety | a hundred thirty | one hundred seventy five | 7.nine | 217 | 124 | 2.6 | ||||||

| Z3-95 | 95 | one hundred thirty five | 205 | nine.nine | 257 | 149 | 10 | 2.7 | |||||

| Z3-100 | one hundred | one hundred forty five | 68 | 58 | 40.eight | 220 | 11 | 192 | 114 | 3.7 | |||

| Z3-a hundred and five | 105 | a hundred and fifty | 220 | 11.55 | 210 | 114 | 3.9 | ||||||

| Z3-one hundred ten | 110 | one hundred fifty five | 220 | 12.1 | 175 | 107 | four | ||||||

| Z3-a hundred and twenty | 120 | 165 | 260 | 15.7 | 192 | a hundred and twenty | twelve | 4.3 | |||||

| Z3-one hundred twenty five | a hundred twenty five | one hundred seventy | 320 | 17.5 | 189 | 120 | 145 | M12 | 10 | 4.eight | |||

| Z3-130 | a hundred thirty | a hundred and eighty | 320 | 20.7 | 188 | a hundred and twenty | 5.nine | ||||||

| Z3-one hundred forty | 140 | one hundred ninety | 320 | 22.5 | one hundred seventy five | 114 | six.3 | ||||||

| Z3-150 | one hundred fifty | two hundred | seventy seven | sixty five | 45.four | 380 | 28.five | 196 | 130 | 12 | 6.7 | ||

Company Profile

FAQ

Shipping and delivery

china shop Locking Assembly Standard Light Machinery Keyless Shaft Power Lock Z22 manufacturers

Merchandise Description

SC Transmission Locking Assembly Regular

Gentle CZPT ry Keyless Shaft CZPT Lock

Merchandise Description

Merchandise Parameters

| Element no. | Size | Dimen sions | Rated Load | Contact Pressure | Locking CZPT s | Bodyweight | |||||

| (mm) | (mm) | (Approx) | |||||||||

| d×D×L | L1 | LW | (Kg) | ||||||||

| Axial(KN) | Torque | Shaft | Tightening | ||||||||

| (N.m) | (Mpa) | (N.m) | |||||||||

| Z22-017 | 17×50×50 | 44 | fifty six | 24 | 200 | 118 | 17 | .five | |||

| Z22-018 | 18×50×50 | forty four | 56 | 24 | 220 | 109 | 17 | .46 | |||

| Z22-019 | 19×50×50 | 44 | fifty six | 24 | 230 | 96 | 17 | .five | |||

| Z22-571 | 20×50×50 | forty four | fifty six | 24 | 240 | 93 | 17 | .5 | |||

| Z22-571 | 22×55×60 | 54 | sixty six | 24 | 260 | 107 | 17 | .six | |||

| Z22-571 | 24×55×60 | fifty four | 66 | 24 | 290 | 96 | 17 | .six | |||

| Z22-571 | 25×55×60 | fifty four | 66 | 36 | 450 | 95 | 17 | .66 | |||

| Z22-571 | 28×60×60 | fifty four | sixty six | 36 | 510 | 84 | 17 | .seven | |||

| Z22-030 | 30×60×60 | 54 | 66 | 36 | 550 | 79 | 17 | .73 | |||

| Z22-032 | 32×75×60 | fifty four | 68 | forty five | 720 | 77 | 41 | one.3 | |||

| Z22-035 | 35×75×75 | 89 | eighty three | 45 | 790 | 82 | 41 | 1.34 | |||

| Z22-038 | 38×75×75 | 69 | 83 | 45 | 850 | 75 | 41 | 1.3 | |||

| Z22-040 | 40×75×75 | 69 | 83 | forty five | 900 | 64 | 41 | 1.4 | |||

| Z22-042 | 42×90×75 | 69 | eighty three | 67 | 1400 | 65 | 41 | two | |||

| Z22-045 | 45×90×85 | 79 | 93 | 67 | 1520 | 73 | 41 | 2.5 | |||

| Z22-048 | 48×90×85 | 79 | ninety three | sixty seven | 1620 | 70 | 41 | two.four | |||

| Z22-050 | 50×90×85 | seventy nine | 93 | sixty seven | 1690 | 64 | 41 | one.95 | |||

| Z22-055 | 55×105×85 | 79 | ninety three | ninety | 2470 | 63 | 41 | 3.3 | |||

| Z22-060 | 60×105×85 | seventy nine | 93 | ninety | 2710 | 59 | 41 | two.fifty five | |||

| Z22-065 | 65×105×85 | seventy nine | 93 | 90 | 2930 | 53 | 41 | three | |||

| Z22-070 | 70×125×100 | ninety four | 110 | 107 | 3770 | 50 | 83 | 5.four | |||

| Z22-075 | 75×125×100 | ninety four | 110 | 107 | 4030 | 47 | 83 | 5 | |||

| Z22-080 | 80×125×100 | 94 | one hundred ten | 107 | 4300 | 65 | 83 | 4.7 | |||

Company Profile

FAQ

Delivery